Did People Suffer For Your Cotton Shirt? DNA Tagging Lets You Track Its Origins

Cotton is a dirty crop, often tinged with human suffering.

Consider the farmers in India, the world’s largest producer of cotton. There, the crop is generally harvested on small farms, where families go into debt to buy seeds from Monsanto, a seed supplier that dominates 90% of the Indian market. As I’ve reported before, it only takes one bad year for a family to lose everything. This has led to an epidemic in suicides, with an estimated 300,000 farmers taking their own lives over the past two decades in order to spare their children the consequences of this debt.

Given devastating figures like these, many consumers understandably want to know more about the origins of the cotton they buy. A solution to that problem is not as far away as you think: Pimacott, the American division of the Indian cotton supplier Himatsingka, has been working on a technology that uses DNA tagging to allow you pinpoint exactly where your cotton comes from. As its name suggests, Pimacott only develops pima, a variety of cotton that is grown largely in the San Joaquin Valley in California and in particular regions of Peru. Because the company focuses on high-end cotton, it needed a way to assure customers that they were getting authentic and unadulterated pima, especially because raw pima might be brought overseas to be woven and turned into products.

“In the industry, there was an increasing discrepancy between what was written on the package of a cotton product and what the material was actually made of,” says David Greenstein, CEO of Pimacott. “There was no really good way to test, so there was less of an emphasis on ensuring the purity of the product. We decided that we were going to use technology to change the way that we source cotton and take control of our supply chain.”

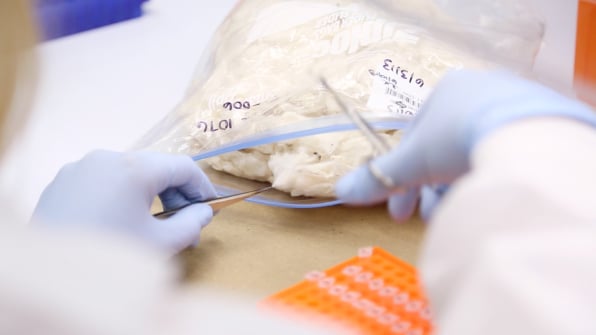

To do this, Pimacott has partnered with Applied DNA Sciences, a U.S. tech firm, to develop a DNA tagging mechanism for its cotton. The technology essentially creates a minuscule marker–much like a bar code–on every grain of cotton. “We apply it during a step that the gin has to do anyway,” says Jim Hayward, CEO, Applied DNA Sciences. “Our goal is always to have no impact on the process.”

This insertion process happens at the gin: Little molecules are released into the cotton and permanently bind to it. From this point onward, it is possible to place a piece of cotton or fabric under a simple DNA scanner to see whether the marker is present. “This concept of using DNA tagging and following it throughout the supply chain is encapsulated in what our brand is trying to do,” Greenstein says. “It’s a trust mark that is meant to educate the American consumer about the source of the material.”

For this system to go into effect, Pimacott has had to start at the very source of the cotton, at the farm level. It has been working closely with its farming partners to incorporate this DNA tagging process into their system. Take Cannon Michael, a farmer who runs Bowles Farming Company in the Central Valley of California. Michael runs a progressive farm that is focused on sustainable practices. “California is a higher cost environment than any other cotton-producing region,” Michael says. “We have higher regulatory costs than anywhere else in the world, the highest minimum wage, and the best worker protections. We have to compete on quality and consistency.”

He is a proud grower of pima–among other varieties of cotton–so he was pleased that this new step would allow Pimacott to guarantee that the pima picked on his farm would not be blended with lower-grade cotton. “We spend so much time on our farm caring for that crop all year round, from the little seedling all the way to the final product,” he says. “To think that we’re producing this really high-quality fiber that was being diluted with lower-quality on such a massive scale–this blending and cheating–is so disappointing. Having a way to clean that up was invaluable.”

Michael, whose farm is part of a collective of family-owned farms, already invested in the infrastructure for the gin. The new technology required a part of the gin to be updated and reconfigured, so they paid to upgrade it. But Pimacott is helping to defray the cost of the marking material. “It’s sort of a group collaboration,” Michael says.

Keeping Cotton Clean And Why It Matters

Cotton is a vulnerable crop that is easily destroyed by insects, requiring farmers to douse their fields with pesticides. In developed countries, farmers have equipment and proper procedures to keep them safe, but in places like India, China, and Pakistan, small, family-owned farms have no such safety measures in place. Laborers exposed to pesticides have a much higher rate of cancer than the general population, and the chemicals are known to end up in the ground water, poisoning entire villages.

Conditions of cotton workers around the world are harsh. But in places like Uzbekistan, they are criminal. There are slavery rings that snatch people from their homes and families, putting them to work in cotton fields–a situation not unlike the slavery that contributed to the production of cotton in the United States a hundred and fifty years ago. It is estimated that 1.2 million Uzbeks live in slavery–4% of the population–because of the cotton trade. Many of them are children.

There was a time when cotton was milled close to the place where it was picked. Indian cotton, for instance, would be grown in one village, then taken to another nearby village to be turned into fabric, which would then be made into saris that would be sold to people in that region. But over the last few decades, the global supply chain has gotten increasingly complex, which makes it very hard to identify the source of cotton. Small farmers sell their crop to middlemen who consolidate the cotton and sell it on the global cotton exchange. Cotton from many countries is often mixed together, then taken to yet another country where a massive industrial mill will turn it into fabric.

By the time the cotton fabric gets to clothing and home goods manufacturers, it is sometimes close to impossible to ascertain the source of the textiles. Last November, both Target and Wal-Mart came under fire for claiming to sell cotton bedsheets that were made of Egyptian cotton, but that were actually blended with lower-quality cotton. After several different customers filed complaints about the mislabeling of cotton products, Target sent a team of investigators to get to the bottom of where the sheets came from, painstakingly studying fibers under microscopes and digging into the complex supply chain for months, only to discover that 750,000 of its Egyptian cotton products had indeed been falsely marketed.

Target and Wal-Mart had purchased the sheets from a $3 billion Indian cotton conglomerate called Welspun, whose stocks went into a downward spiral after this scandal came to light. Target immediately pulled its $90 million in annual business; Wal-Mart and Bed Bath & Beyond followed suit. “The issue was about traceability, not about quality,” said Welspun’s chairman, Balkrishnan Goenka, at a press briefing in the aftermath of the fiasco.

A Good Beginning

Now that Pimacott has set up its system across the network of farmers it partners with, it will be able to work with manufacturers and retailers to market products as “Pimacott-certified.” At present, it has an exclusive partnership with Applied DNA Sciences, but the DNA tagging technology is not complicated and could be easily replicated around the industry. The question is, will other cotton suppliers want to follow suit?

The Cairo-based Cotton Egypt Association (CEA), which certifies products that are made from Egyptian cotton, is also investing in DNA tagging technology. Like Pimacott, the success of its business depends on building trust with the consumer and guaranteeing that products are pure. In April, it formally announced that it would be developing a DNA testing program, but one of the first companies that received certification was Welspun, the very company that was producing blended-cotton products. Target says that it will no longer rely on CEA’s certification; Wal-Mart, for its part, says it would continue using it.

But for this technology to be truly powerful, it would need to go beyond the few countries that produce high-end extra-long staple cotton. Monsanto, which is the world’s largest seller of cotton seeds–and dominates up to 90% of the market share in countries like India–could incorporate this tagging technology into its vast network around the world. This would allow manufacturers and consumers to trace the complex supply chain and assess the quality of cotton that is being used. However, it may have incentives not to do so. After all, many farmer suicides can be traced back to the steep prices of cotton seeds that Monsanto sets, and pesticide deaths can be attributed to the chemicals that Monsanto sells along with seeds. The company might want to stay away from technology that would identify it as the source of these tragedies.

For the time being, it takes a lot of effort to ensure that cotton purchased from developing countries is free of suffering. In India, a small number of organic cotton farms have sprung up. They’re being driven by organizations like Chetna Organic, a co-op that helps 105 different farms and 35,000 farmers pool their resources, use organic approaches to reducing pests, and strategize about how to use money for the collective good, like setting up schools and medical centers. Chetna has also set up mills and manufacturing facilities, so the cotton can be immediately spun and turned into products, allowing it to stay on top of the supply chain.

Sukanta Nanda and his wife, Namrata, grew up in cotton producing regions in India but have spent the last few decades in the United States working for Microsoft. In 2014, after watching a documentary about the horrors that Indian cotton farmers experience, they decided they wanted to invest in India’s organic cotton industry, so they launched a direct-to-consumer luxury sheets company called Syona Home, which targets American consumers who are interested in more ethical cotton products. They’ve worked with Chetna to produce a line of sheets that hit the market last year.

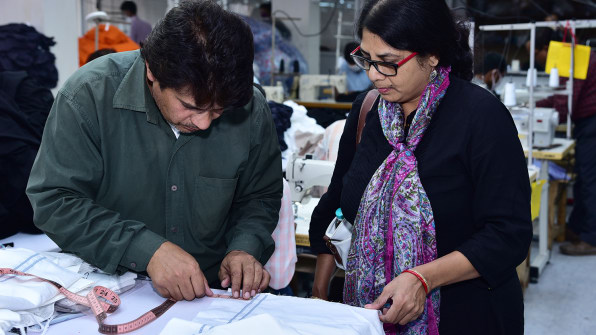

But the Nandas didn’t want to take the word of Chetna about how workers were treated. After all, nothing is straightforward when it comes to cotton: Raw cotton goes through so many steps, in so many corners of the world, before it ends up in a pair of bedsheets. As Indians, they believed they were in a position to investigate each step of the process. “I wanted to go there and make sure the workers were treated well,” Sukanta explains. “It can be hard to be sure when you’re just talking to leaders of the co-op from miles away.”

Over the last two years, Sukanta has spent days on farms and mills and factories, talking to workers, asking them about their lives. He’s seen how his company’s bedsheets are made from end-to-end. He believes this is what it takes, given the current cotton supply chain, to ensure that the cotton you’re buying is ethically made. For now he’s right: But in another world, one where DNA tagging technology is widespread, a maker of bedsheets wouldn’t need to go all the way to the source to keep the cotton supply chain honest. Maybe then we could all sleep better at night.

Fast Company , Read Full Story

(63)