How IKEA Designs Its (In)famous instruction Manuals

Love ’em or hate ‘em, numerous idea goes into that Ikea stuff you throw away after meeting.

October 28, 2015

everybody has an Ikea horror story. My spouse’s work desk, for instance, took her and my sweetheart’s mother a whole day to collect, shifting ahead only in matches and starts with typical intermissions for cursing. (I’d have helped, but I was once quite simply absent for causes i will’t keep in mind.) Even Ikea itself seems to have usual this reputation. “A newspaper in Sweden described Ikea [furniture assembly] as one thing between civil engineering and captaining a submarine, and i think that’s a excellent description,” says Allan Dickner, Ikea’s deputy packaging supervisor.

still, there’s one foolproof manner for turning Ikea rage into grudging respect: assembling virtually any other brand of furniture. After an hour spent evaluating piles of ambiguous parts in opposition to an meeting diagram that gave the impression of a misfiled mimeograph from space fifty one, I in some way produced a HomeGoods finish desk—as well as a surging curiosity about how Ikea designs its personal packaging and directions, which now appeared positively Eamesian when put next. To adapt Winston Churchill’s well-known quip, Ikea is also the worst form of prepared-to-bring together product design we have—apart from for all of the others.

in line with Allan Dickner, whatever your most irritating Ikea expertise is, it will possibly were worse—and possibly was once for the packaging engineer who check-assembled much more difficult versions of the product earlier than arriving on the optimized design that you unboxed in your lounge ground. “We had one furnishings piece, a type of cloth wardrobe, which originally had over 400 fittings and screws to hold it together,” Dickner says.

after all, this extreme “knock-down”—the trade time period for disassembly of merchandise to make them more straightforward and more cost-effective to ship to buyers—is a huge the reason is, that Ikea dresser is so inexpensive. “but when it takes any individual 5 hours to build it, you can ask your self: have you gone too a ways with the flat packing?” Dickner provides. “It’s always about discovering a stability between ease of meeting and optimizing the packaging.” (That wardrobe, for the record, used to be redesigned to “knock down” into fewer elements.)

Ikea’s flat-packaging engineers are included alongside product designers within the preliminary briefings for any new Ikea offering. however after a half-century of flattening bookshelves and armoires, Ikea doesn’t wish to reinvent the wheel very often. For 80% of ready-to-assemble products, Ikea packaging engineers depend on what Dickner calls “confirmed options”: generalized templates that the engineer nips and tucks to compare the specifications of a brand new item.

These proven options aren’t simply algorithmically optimized (although they’re that)—additionally they include on-the-ground information about living conditions in the entire countries where Ikea furniture is sold. “it could be fairly silly to design a package deal that’s flat and environment friendly but gained’t fit into a small elevator or staircase,” Dickner explains. “It sounds ridiculous, however in the United Kingdom, that used to be one of the most widely wide-spread reasons for a customer returning a product.” He adds that global package designs are tested in Japan and South Korea “as a result of those are the customers who are living within the smallest areas.”

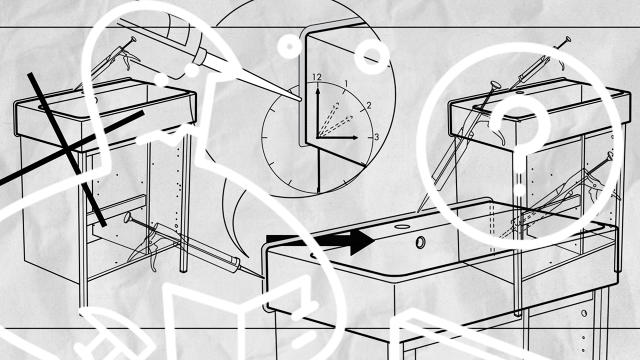

Turning a 3-dimensional couch right into a pseudo 2-D flat-packed jigsaw puzzle isn’t any imply design feat. but when the meeting directions don’t make sense, all that work is moot. in keeping with Jan Fredlund, an clothier who works on these guideline booklets, there are two guiding ideas at the back of each page: clarity and continuity.

the primary time period is apparent enough, but Ikea takes it severely enough that guide designers (or “communicators,” consistent with Fredlund) begin by way of putting a product together themselves. “test assembly offers a possibility to search out out if there is a chance that the customer would possibly position a certain phase within the mistaken direction which may not look like an obvious mistake in the moment, but will cause a problem many steps later,” Fredlund says.

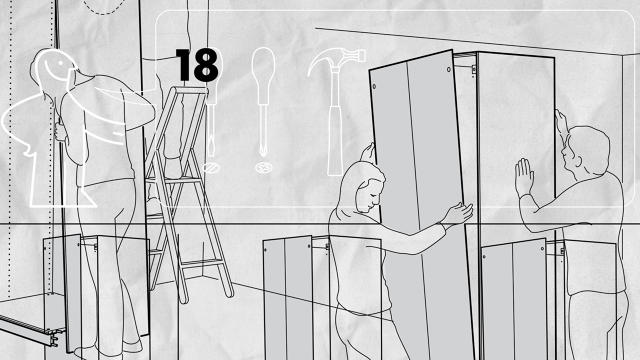

Continuity, in the meantime, is what separates Ikea’s directions—even the maddening ones—from these of other brands. The Lego-like, frame-by using-body illustrations are according to development drawings, digital snapshots, three-D models, and videos of take a look at assemblies. Designers take pains to render every successive image from a single, unchanging level-of-view (mimicking that of the client), so that complicated rotations or viewpoint modifications are minimized and the buyer can stay oriented extra simply as she or he strikes back and forth between the booklet and the parts.

If the end outcome does infrequently feel like a civil engineering project (as Dickner admits with some satisfaction), it’s because a high stage of precision and redundancy is exactly what undergirds even probably the most complex or tedious Ikea assemblies. They is probably not nice, but they are as a minimum rational and comprehensible—even sympathetic—through design. call to mind that enormous-nosed “Ikea man” who’s proven calling the corporate when he gets stuck. He’s now not mocking or condescending. If anything, he represents some designer at Ikea who has already long past thru precisely what you’re going through now to your front room flooring: half of-quizzically glancing from guideline booklet to pile-of-elements and back, hoping for the very best, however trusting that it will all, at the very least, make feel.

fast company , learn Full Story

(260)