3D-printed ‘living ink’ could lead to self-repairing buildings

New 3D printing technique could make lab-grown organs more practical

You could have healthier parts ready in minutes, not hours.

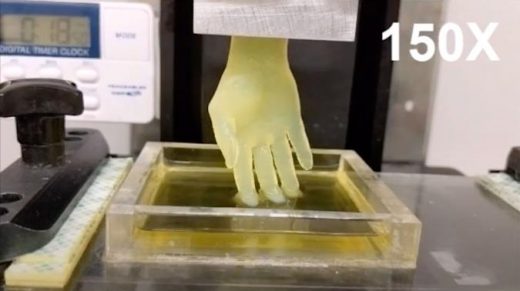

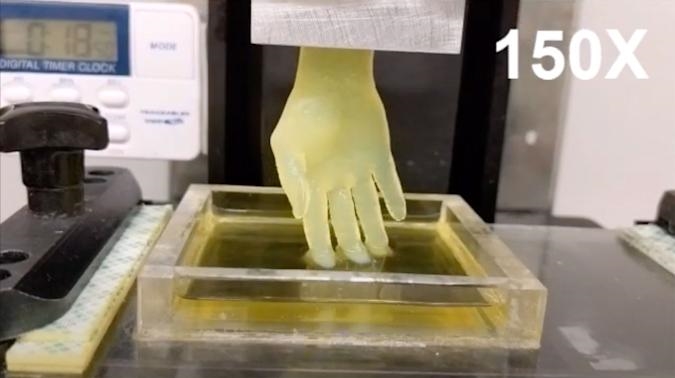

As much as 3D-printed organs have advanced, creating them is still a slow process that can damage the tissue. There may soon be a quicker and more effective method, however. Researchers from the University at Buffalo and elsewhere have developed a 3D printing technique that’s 10 to 50 times faster than standard methods. A tiny synthetic hand (shown above) that would have taken six hours to print took just 19 minutes — enough to minimize the deformation and cellular damage from earlier systems.

The new approach uses a combination of stereolithography with hydrogels. By precisely guiding photopolymerization (curing the material through light), the team could quickly and continuously supply the necessary hydrogel solution and maintain “nonstop” growth. It’s akin to paving a new road mere moments before you drive on it.

The output is currently limited to “centimeter-sized” models, but it’s already well-suited to printing cells with built-in blood vessel networks. That will be crucial for the eventual production of human-sized organs. If scientists can scale the process to full-size organs and make it suitable for everyday use, hospitals wouldn’t have to rely so much on organ donors for life-saving transplants.

(8)