A Startup’s Plan To Cut Air Freight Costs In Half With 777-Size Drones

Commercial passenger jets fly at an altitude of around 30,000 feet or higher. Imagine sitting in a window seat of one of those giant aluminum tubes a few years from now as it makes its way across the Pacific Ocean. Picture looking down about 10,000 feet below. You just might see what one startup thinks could be the future of international cargo transport.

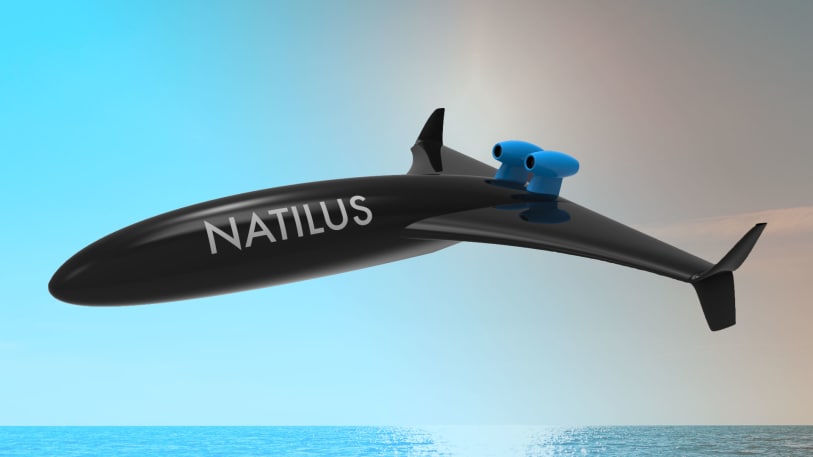

The idea is simple: Shipping by air is fast, but expensive. Boat is much cheaper, but very slow. So why not send all those boxes and packages on an un-piloted, amphibious Boeing 777-sized drone that can fly point to point and eventually drop off as much as 200,000 pounds of cargo at a seaside port? It would carry that cargo at about half the cost of normal air freight thanks to a more efficient use of fuel and the lack of an expensive crew.

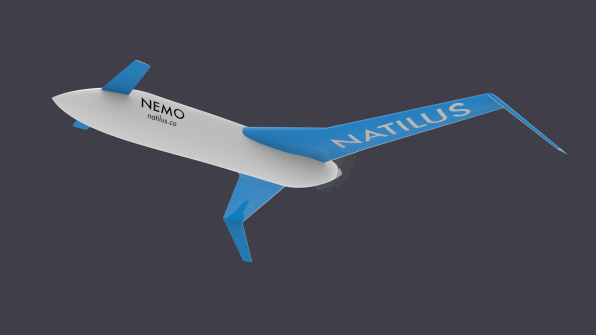

That’s the thinking behind Natilus, a Richmond, California-based startup that this summer plans on flying FAA-approved tests of a 30-foot prototype that’s about the size and weight of a military Predator drone. The flight will mark the first significant step toward upending the global freight forwarding industry. Eventually, CEO Aleksey Matyushev says, the company hopes to fly the prototype on 30-hour test runs, carrying up to 700 pounds of cargo, between Los Angeles and Hawaii.

Natilus, which has raised $750,000 from venture capitalist Tim Draper and was incubated at the aviation-oriented Starburst Accelerator in Los Angeles, will power its drones with turboprop and turbofan engines and standard jet fuel, sending them on missions at an altitude of approximately 20,000 feet. That’s well below commercial planes, but high enough to be fuel-efficient. Matyushev says trips across oceans would cost about half of what current commercial air freight transport runs, traveling a bit slower than manned cargo aircraft.

Because the drones would be unlikely to receive government approval to fly over populated areas, they are designed to take off and land in the water. They don’t even have landing gears. The expectation is that after landing, they would taxi into a standard port, where cargo would be unloaded using cranes.

The goal is to finish production of the full-scale, over 200-foot drone by 2020, then have it undergo testing and certification before beginning actual commercial flights. Natilus hopes to build hundreds of the drones, some of which will be sold directly to customers—ideally to companies like UPS and FedEx as well as “medium freight forwarders” like Whole Foods and Costco. Matyushev notes that Natilus may operate some of the drones itself as a freight airline but fly them under the brand logos of customers. (When asked to comment on Natilus’s plans or the future of drone delivery in general, a UPS spokesperson declined to comment, “other than to say that we see promising potential applications in a number of areas.” The company adds that it has already been testing drones for a variety of applications, ranging from humanitarian aid to commercial delivery and inventory inspection.)

Though Natilus is still several years away from delivering drones—it currently operates with just three core staffers and less than a million dollars in funding—Chris Connell, president of the global perishable goods transporter CFI, says he is “intrigued” by the company’s concept.

“Air cargo is all about speed at high price,” he says. “Ocean freight is longer transit times at lower pricing. And with certain goods—be it perishables, or goods that are looking for that middle ground—that idea of middle price for middle transit times is that sweet spot.”

Connell says he’s used to end-to-end transit times of as much as seven days to send cargo from the West Coast to Hawaii by ship. He has the option to pay a premium to send it by air cargo for same-day arrival. But in many cases, there could be an argument for the middle ground that Natilus is aiming for, where cargo can be delivered to its destination in about three days, once loading and unloading is taken into consideration.

For that much of a time savings, Connell considers the 20% premium over ocean freight prices that Natilus would charge well worth it, especially when it comes to pre-prepared perishables such as salad kits, sandwiches, and other items that could be assembled off-shore, in places where labor is less expensive.

One of Natilus’s goals is to use lower shipping costs to reduce the price of goods to consumers. “That’s the grand vision,” Matyushev says. Connell thinks that’s possible, but says the benefit may simply be fresher goods that arrive faster.

For now, Natilus is focused on getting its 30-foot prototype, which is about 70% complete, ready for summer tests in San Pablo Bay, just northeast of San Francisco. If those go well, then it’s full steam ahead on the 777-sized model, provided that additional funding and the engineering talent needed to build it materialize.

It’s too early to know if Natilus, or anyone else, can successfully develop these massive unmanned aircraft. But ever since Amazon famously unveiled its plans for drone deliveries during a 2013 episode of 60 Minutes, there’s been substantial interest in unmanned shipping, Connell says.

Amazon and other companies are talking about using small drones for their deliveries, but Connell thinks an advance like what Natilus is pursuing, which could exploit a big gap in the current shipping markets, is inevitable.

“Airplanes aren’t going to slow down,” he says. “And boats aren’t going to go faster. The drone concept adds something new. It adds to the intrigue.”

Fast Company , Read Full Story

(27)