Chipotle Eats Itself

Chipotle’s annual shareholder meeting on May 11 was set to be a doozy. Angry activists and investors were poised to unload on the restaurant chain’s co-CEOs, Steve Ells and Monty Moran.

Just two weeks prior, Chipotle had reported a $26.4 million quarterly loss—its first in a decade as a public company—following a high-profile E. coli outbreak and several subsequent food-safety incidents. Nearly one-third of restaurant sales had disappeared, and the stock had sunk by 30%. An attempt to shake up the company’s board of directors was almost certain, reports said. Its “failures,” as one major investment adviser had phrased it, “damaged the brand and erased billions in shareowner value.” Ten billion dollars since its peak, to be precise.

I arrive at Denver’s Grand Hyatt hotel shortly before 8 a.m. The meeting space, a windowless conference room, is surprisingly small and awkwardly intimate, with just three rows of nine chairs facing a cloth-draped table. Apparently, this is standard for Chipotle’s annual meetings, as is the fact that the proceedings are closed to the press. (I find my way inside by showing that a mutual fund in my 401(k) includes Chipotle shares.) As board member Kimbal Musk strides to the front row, he surveys the tiny room and jokes to another director about how this setting pales in comparison to the elaborate events that his brother, Elon, throws for Tesla’s shareholder meetings.

Ells and Moran march in minutes later and take their seats at the table. “Good morning,” Ells says, coffee in hand. Moran quickly runs through the agenda and other formalities. He soon opens the floor to questions. One of Chipotle’s harshest critics, CtW Investment Group’s Michael Pryce-Jones, stands and berates the company’s CEOs for nearly two minutes. “You’ve gone from a beloved brand to one that’s been unprecedentedly abandoned,” he scolds. Comparing their recent blunders with Volkswagen’s emissions scandal and BP’s Deepwater Horizon oil spill, he implores the board to “seriously consider resignations.”

The two CEOs remain stone-faced. Moran replies, “I think the best plan of action for us at this point is to focus like a laser on the things that have made Chipotle so popular over the years, most notably running terrific restaurants with great food and great customer service.” He tries to move on to another question, but Pryce-Jones interjects to press his case again. Moran shoots him a grave look and cuts him off, saying: “That’s the answer.”

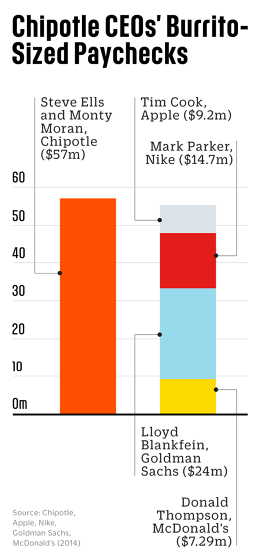

The tongue-lashings continue. A codirector of the Food Chain Workers Alliance, an advocacy group for restaurant-industry and supply laborers, calls Chipotle’s leadership “nonresponsive” and demands better treatment of the people who provide its food. There are complaints about executive salaries—Ells and Moran together took home $57 million in compensation in 2014, more than the total pay packages of the CEOs of Apple, McDonald’s, Nike, and Goldman Sachs combined—and the lack of diversity among its directors. Chipotle’s board is all-white, with a median tenure of 17 years.

Many of these appeals are not new. Some of the people here are perennials at Chipotle meetings, arguing similar agenda points year after year. Today, though, they’re delivered with renewed vigor—as if this time, after all it has been through, maybe Chipotle will finally listen.

After 37 minutes, Ells ends the meeting. No one resigns. There are no changes to the board. Most votes had already been cast before the meeting, and the majority of investors supported management’s wishes. The only victory for dissatisfied shareholders? A resolution that will give anyone who owns at least 3% of the company’s stock the ability to nominate their own candidates to the board.

As I watch Ells smile for a photo (with one happy shareholder in attendance) before he makes a hasty exit, there’s a sense that Chipotle management just went through the motions at this meeting. They certainly haven’t used the opportunity to try to win back former supporters.

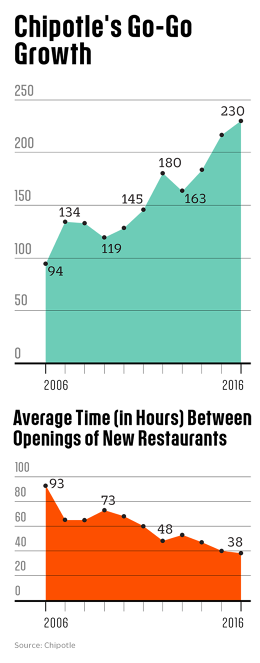

For years, enlightened restaurant-goers, shocked and horrified by Fast Food Nation, pink slime, and the evils of Big Food, have felt an almost religious pull to Chipotle’s “Food With Integrity” mission—its commitment to fresh ingredients, ethical sourcing, and disrupting the fast-food model—as if eating at a Chipotle could nourish your soul as well as your body. The company grew from a single storefront in Denver in 1993 to around 2,000 locations, becoming the envy of the industry for its premium ethos (and pricing), as well as innovations like its theatrical-yet-efficient assembly-line service. Chipotle became a go-go growth stock. If you had bought 100 shares at Chipotle’s 2006 IPO price, it would have cost $2,200; by the time the stock peaked in 2015, just before the outbreaks, that stake would have been worth $75,700, a 3,340% increase.

The E. coli bacterial outbreak, which became national news as reports of sickened individuals streamed in during the fall of 2015, shattered everything. It wrought devastation far beyond the 60 people who fell ill. (Norovirus and salmonella incidents bookended the E. coli poisonings and ultimately brought the total number of customers affected to 500 people across 14 states, but Chipotle feels those episodes were isolated cases.) An average Chipotle serves 60 customers in 30 minutes. On any given day before the crisis, Chipotle serviced the equivalent of the population of Philadelphia. No one knows definitively which ingredients may have been the culprit. But each burrito includes one ounce of romaine lettuce. So, if those leafy greens carried the bacteria, that means about five $2.50 heads of grocery-store lettuce erased more than $10 billion in market cap. Or if cilantro was the source, then about as many cups of it as you’d find in a cookout-size batch of guacamole.

When a listeria outbreak caused by Dole’s packaged salads was linked to four deaths last year, the public outcry was not nearly as intense or sustained (despite an ongoing federal investigation). When Tesla reported its first driver fatality while using its Autopilot feature last June, it didn’t affect the company’s stock price at all. Why were these deaths only blips for Dole’s and Tesla’s reputations? By contrast, Chipotle spent a year in hell even though no one died—and more than 265,000 Americans get sick annually from illnesses linked to E. coli.

It’s understandable, perhaps, that some Chipotle insiders feel the company has been unfairly judged—by health regulators, the media, and its own customers. Yet Chipotle has had no choice but to grapple with the reality that its prestige status has evaporated. And there is no obvious road map for gaining it back.

Despite Ells and Moran’s posture in the shareholder meeting, this crisis has rocked their faith. “Steve and I live for this company. We are deeply about our mission,” Moran says when we meet in late June. “For something like this to happen shook the foundations of our confidence… it causes one to question one’s leadership.”

I spent seven months following the company’s efforts at recovery. The journey took me from rural farms to industrial kitchens, from the hotbeds of Chipotle’s outbreaks in Massachusetts to its fan festival in Arizona, from a summit of food-safety experts in Illinois to the company’s corporate offices in Colorado and New York. I talked to scores of restaurant employees—and I ate more burritos than I can count (never once getting sick). I interviewed the co-CEOs, other top executives, current and former employees, suppliers, and food-industry partners, and I reviewed more than 1,000 pages of internal documents. The story that emerges from all this is provocative and unexpected, a tale of optimism, hubris, bad luck, and missed opportunity.

Chipotle has said it won’t be satisfied until it’s regained all of its lost sales and resumed its momentum. It has pledged to continue to refashion the food system. As a longtime customer, I want to believe them. Everyone wants to believe them. But as I learned, what’s ailing Chipotle is more pervasive and insidious than any foodborne illness. For Chipotle to win back all it has lost will require a soul-cleansing broader than perhaps even Ells and Moran realize.

[Illustrations: Nicole Rifkin]

Chapter 1: The Outbreak

Searching for the culprit.

On October 19, 2015, Jared Hines, a 21-year-old college senior, went to a Chipotle restaurant near downtown Seattle for dinner. He ordered a chicken burrito with white cilantro-lime rice, black and pinto beans, pico de gallo, corn salsa, cheese, and lettuce. He scarfed it down and thought nothing more of it.

Four days later, pain seized his 6-foot-3, 160-pound body. A 101-degree fever. Vomiting. Diarrhea. Then things got worse: “I had blood pouring out of me from every orifice,” he tells me.

His parents rushed him to the hospital, where doctors, assuming he was reacting to a recent bout of mononucleosis, prescribed antibiotics.

Hines remembers coming to in a hospital bed days later, surrounded by his parents, his girlfriend, and a doctor who explained that he was “rotting from the inside.” Hines had contracted a strain of E. coli, known as 026, which was spewing a harmful toxin into his body and essentially shutting down his internal organs. The antibiotics he’d been prescribed likely accelerated the toxin’s release. His weight had dropped to 145 pounds. Kidney failure, even death, were very real possibilities, the doctor said.

A nurse arrived soon after to hand Hines a telephone. It was a local health official asking where and what he had been eating. Hines, still frail and depleted, wracked his brain to list off recent meals and restaurants. Then the voice on the line perked up. “Did you say Chipotle? We need you to remember your order right now.”

Chipotle executives say they learned of the first E. coli cases from health authorities on October 30. Soon, dozens of people showing symptoms of E. coli poisoning were linked to eight restaurants in Washington and Oregon. Because the company serves 1.5 million customers per day across the country, they quickly realized that if the outbreak was more widespread, it could be catastrophic. “It was really frightening,” says Moran, who remembers thinking, “My goodness… was [this] really us?” Recalls Ells, “It all caught us off guard. Nothing like this had happened. The magnitude…”

Over Halloween weekend, Moran and Ells made the decision to shut down 43 restaurants in the Pacific Northwest in an effort to contain the outbreak. Chipotle’s stock price, which had hit $757 just weeks earlier but had been showing volatility surrounding a weak fall earnings quarter, slid to $624 on Monday, November 2.

The company scrambled to get ahead of the crisis. It brought in food-safety scientist Mansour Samadpour, who runs a Seattle-based consultancy. He helped the company eventually run thousands of tests on Chipotle’s food, searching for indicators that it had been contaminated. Moran himself took Samadpour on dozens of unannounced restaurant visits around the country to examine operations. “It was just all hands on deck,” says Chipotle CFO Jack Hartung.

To some restaurant workers, it felt like chaos. One manager recalls receiving urgent word one day from superiors that their cilantro was contaminated. “They told us not to put cilantro on anything and throw it all away, in all the restaurants,” this source says. “Then, an hour later, they’re like, ‘False alarm! No need to do that.’”

Throughout November and December, Chipotle says its testing found no traces of E. coli 026 within the restaurants or its food. Because the bacteria’s effects are delayed, the tainted food was likely already gone from Chipotle’s system not long after the first illnesses were reported. To an audience of investors, Chipotle blamed the Centers for Disease Control and Prevention (CDC) for stirring up public alarm about an issue it felt was contained. “[The panic has] been fueled by the sort of unusual and even unorthodox way the CDC has chosen to announce cases related to the original outbreak in the Northwest,” Moran told attendees of the Sanford C. Bernstein Consumer Summit on December 8. “They’re not announcing new cases. They’re just simply announcing new reporting to them from local health agencies.” A CDC spokesperson says that this is standard practice.

Chipotle says that not a single employee was infected, which led to watercooler talk of Chipotle being a victim of corporate sabotage. Many sources, even respected luminaries in the food industry, have suggested to me that Monsanto, the agribusiness biotech giant that became a target of Chipotle’s vociferous stance against genetically modified foods, could have somehow engineered this crisis. (Ells has dismissed this to colleagues in private as a “conspiracy theory.” A Monsanto spokesperson says, “There’s a lot of misinformation about Monsanto online, and this conspiracy theory is an example of that.”)

Both Chipotle’s and the CDC’s investigations were further complicated by their struggle to isolate ingredients within the meals that victims ate. Many of Chipotle’s menu offerings contain the same ingredients and are often prepared in small kitchens, so cross-contamination was likely. “The problem is you can’t find someone who didn’t also eat the beef, or didn’t also eat the lettuce,” explains a senior CDC official. “The case went cold.”

Years earlier, Chipotle had announced a partnership with a company that makes a food traceability program, designed to assist with exactly this type of investigation. The provider, FoodLogiQ, purported that its software offered “real-time visibility of food” at every point in the supply chain, akin to how a consumer can track an Amazon package online. A 2014 case study of the Chipotle–FoodLogiQ deal even touted how the system could locate the origin of spoiled food within minutes. Despite these claims, Chipotle never got around to implementing FoodLogiQ at its restaurants. (Chipotle spokesperson Chris Arnold says the FoodLogiQ installation was a multiyear process, which was on track and has since been completed; he says its partial implementation did not impede the company’s investigation.)

The CDC concluded its investigation February 1, declaring that the “outbreaks appear to be over.” It did not publicly identify a cause. According to sources familiar with the inquiries, Chipotle narrowed its focus to a select few items, including onions, cilantro, and the beef it imports from Australia. Ells declines to share his theories on what spread the E. coli. “It would be irresponsible for me to say what thing might have caused it because we can’t say definitively,” he explains. “Having a very scientific analysis of this is different from having an opinion of what it might be.”

But that didn’t mean Chipotle could afford to sit by and call the outbreaks a fluke. With no single culprit, its entire food-prep process came under scrutiny.

Chapter 2: Fresh Troubles

Simplicity under the microscope.

Ells’s vision for Chipotle always prioritized fresh ingredients and preparation. “When I created Chipotle in 1993,” he has said, “I had a very simple idea: Offer a simple menu of great food prepared fresh each day, using many of the same cooking techniques as gourmet restaurants. Then serve the food quickly.” Walk into any Chipotle and you’ll see that model humming. As many as 16 employees will be staffing the line and kitchen. Customers queue up, sometimes hundreds per hour, and choose among four meal items—burritos, burrito bowls, tacos, and salads—and sides, all made from just 64 ingredients. (By contrast, a Big Mac alone contains more than 70.)

Ells, an epicurean who worked in the early 1990s under legendary chef Jeremiah Tower, not only obsessed over culinary craft—he claims he can tell the temperature of a Chipotle grill simply by eyeing the smoke rising from it—but also every aspect of his customer experience. Despite his slight build and introverted personality, Ells can be demanding in his pursuit of exactitude and, according to former colleagues, prone to Gordon Ramsay–esque outbursts. Once, on a restaurant visit, Ells lost his cool when he heard how much racket a set of new stools was making when dragged against the floor. “They’re too damn noisy!” he yelled at his team, according to two sources. “I never want to see one of these stools again!” It didn’t matter that he’d approved their design, or that they’d already been shipped to around 50 stores. (Arnold, the Chipotle spokesperson, says, “I am not aware of this incident.”)

As Chipotle has grown, its operation has evolved to be anything but simple. The company purchases 185 million pounds of what it considers responsibly raised beef, pork, and chicken annually. The raw meat it prepares at its restaurants—as opposed to the highly processed, often-frozen goods that other fast-food outlets serve—must be handled and cooked properly, or else potentially harmful pathogens will blossom. Much of Chipotle’s produce has traditionally been prepared at its stores too. “We would go through millions of pounds of cilantro! That’s such a dangerous item—so many nooks and crannies where E. coli can hide,” says one former Chipotle supply-chain executive. “As much fresh produce as they deal with”—Chipotle goes through more than 200,000 pounds of avocados daily—”in retrospect, I can’t believe somebody didn’t raise a red flag. Did their volume catch up to them?”

Before the crisis, the chain had relied on 60,000 mostly low-wage workers (the average hourly pay is $10 per hour) to properly sanitize, dice, and cook ingredients such as lettuce, avocados, tomatoes, as well as raw chicken and steak. Chipotle has an annual turnover rate of 130%, meaning the average store will replace its entire head count at least once per year. “By the time someone learns how to handle a knife and not stick their hand in their ass before handling food, they have left,” says a source familiar with Chipotle’s food-safety program. Now consider that Chipotle opens more than 200 new restaurants annually, or the equivalent of about one every 48 hours. It once hired 4,000 new employees in a single day.

Because of Ells’s high standards and insistence upon preparing pork and some beef through time-consuming techniques such as braising, Chipotle has had to employ the same third-party, industrial-scale “central kitchens” that work with fast-food giants such as McDonald’s and Subway. The term is sort of a euphemism Chipotle uses for these outside partners, which help the company handle, distribute, and even source some of its ingredients.

Before the E. coli outbreak, multiple sources tell me that this blended operation—centralized and in-restaurant kitchens, with food from scores of global suppliers being shipped to both—had just four people assigned to quality assurance (QA), a low number for a chain of Chipotle’s scale and complexity. (Arnold confirms this figure, but says the team was “strengthened” with additional hires after February 2016.) “The way the supply chain was set up, they had hundreds of [suppliers] that were funneling in [raw meat and fresh produce],” says one former analyst at the company, who now works for a chain much smaller than Chipotle but with a QA team that’s twice its size. “There is no way a team that small could properly manage all the food coming into that system.”

The kitchen theatrics that Ells has deftly used to promote his food’s freshness to customers—the sizzling plancha, the tortilla grill—obscured that it was less safe than conventional fast food. The company had disclosed this fact to investors long before the crisis. In its 2013 and 2014 annual reports, it acknowledged: “We may be at a higher risk for foodborne-illness outbreaks than some competitors due to our use of fresh produce and meats rather than frozen, and our reliance on employees cooking with traditional methods rather than automation.”

Chapter 3: Panic In The Kitchen

Reactions, overreactions, and playing the blame game.

ln the months following the crisis, the company, advised by Samadpour and also Dave Theno, the food-safety expert often credited with saving Jack in the Box after its 1993 E. coli crisis, set about overhauling Chipotle’s approach to food safety. But how would it make improvements without resorting to automation like its rivals? “If food is processed—like canned or frozen—you can reduce the risks of pathogens,” Ells tells me. Chipotle didn’t want to do that.

With customers fleeing (and some who remained, joking, “Can I have my burrito without E. coli?”), Chipotle’s executives prioritized safety at the expense of its food and service. “There was no balance,” Moran says, in reference to the company’s quick decision to outsource some items to its central kitchens that it had long prepared fresh in its restaurants. When I mention Moran’s comment to Ells, he says, “We didn’t have a choice.”

Samadpour assisted Chipotle in instituting a food-safety program designed to keep pathogens out of the food chain altogether. It included what Chipotle called “high-resolution DNA-based testing.” Chipotle evaluated samples of, say, raw beef for genetic markers that it might be unsafe. For every 2,000 pounds of meat that went through its system, Chipotle’s suppliers would take 60 subsamples, at around six grams each, and send them to a lab for review. If they passed this quality test—each of which cost roughly $35 and took around 24 hours to complete—the meat would be routed to Chipotle’s restaurants. For produce, this meant the preparation of ingredients such as tomatoes, lettuce, and bell peppers had to be moved to central kitchens, where they would be precut and washed, sampled for testing, and “put in bags so they were ready to use [once shipped to restaurants],” Moran says.

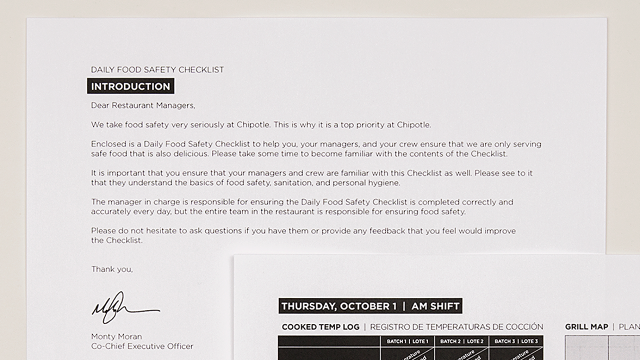

During this period, the company still relied on its Daily Food Safety Checklist, a large document that predated the outbreaks, which the company sent to restaurant managers. In a letter included on the second page of the document, Moran said he expected managers to fill it out “correctly and accurately every day.” Moran, who has been friends with Ells since Boulder High School and joined him at the nearby University of Colorado, is a handsome and charismatic outdoorsman with a firm handshake—”Mr. America,” as one former employee phrases it. After graduating from law school, he rose to become the head of the Denver-based law firm Messner Reeves LLP in his thirties before joining Chipotle, where he brings an attorney’s focus on detail to these types of internal employee guides.

Following the outbreak, there was renewed emphasis on the checklist’s requirements, such as hourly hand-washing in 100-degree water for 20 seconds (“sing ‘Happy Birthday’ twice,” the instructions read) and crew audits, which entailed asking all employees whether they showed symptoms of illness, including vomiting or diarrhea. Additionally, the company now tasked general managers with completing food-temperature logs every hour—that is, ensuring the chicken and beans are properly cooked to an internal temperature of 165 degrees. “All we did [after the outbreak] was take temperatures,” a former general manager bemoans.

Area managers, meanwhile, now had to conduct their own food-safety audits weekly rather than every 45 days. In an email to managers chastising them for not submitting their audits on time, Mike Duffy and Gretchen Selfridge, who effectively act as co-COOs for all of the company’s restaurants, wrote that “your only job right now is to ensure all new procedures and food-safety practices are being executed 100% of the time in 100% of your restaurants.” With so much time spent focused on these audits, one former restaurant manager says, “Attention to service took a back seat and it became more about how we protect ourselves from further incidents.”

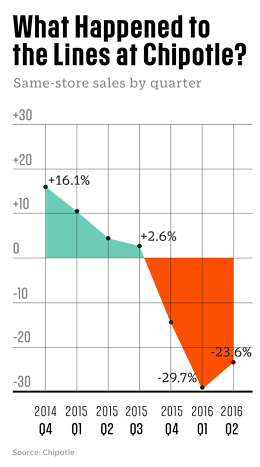

In spite of these measures, in early December, another outbreak hit a restaurant, in Brighton, Massachusetts, near Boston College. Early reports suggested E. coli poisoning may have been to blame, but it turned out to be norovirus. (The outbreak ultimately infected 143 people.) Shortly thereafter, the CDC announced that five more people had been infected with E. coli “and appear to be linked” to Chipotle stores in Kansas, North Dakota, and Oklahoma. Although these cases were unrelated to the larger E. coli incidents that initiated the crisis, all consumers heard was that eating at Chipotle will make you sick. The reports snowballed to create “the impression that, ‘Oh man, this keeps happening,’ ” Moran says. Same-store sales dropped 14.6% for the quarter versus this same period the previous year.

Executives blamed the press for fanning the controversy: Moran told Wall Street analysts at the Bernstein conference, “Because the media likes to write sensational headlines, we’ll probably see when somebody sneezes that they’re going to say, ‘Ah, it’s E. coli from Chipotle’ for a little bit of time. And so that’s unfortunate.” In an effort to reassure the public, the company took out full-page ads in 61 newspapers to apologize and highlight new safety precautions, including the company’s ongoing implementation of high-resolution testing. Ells appeared on NBC’s Today show on December 10, where host Matt Lauer grilled him about whether the chain had grown too fast and “couldn’t keep control of things like sourcing and quality control.” Ells denied that was the case. “If you look at the quality of our ingredients over time, we’ve made great strides in sourcing better-quality food, meats without antibiotics or growth hormones, more organics, more local and sustainably raised foods,” he said. “I’m deeply sorry this happened, but the procedures we’re putting in place today are so above industry norms that we are going to be the safest place to eat.”

In January, not long before Chipotle’s stock dropped below $400, the company sent managers a new “Food Safety Rollout Guide” to highlight the changes that would be phased into Chipotle’s supply chain. The week of January 4, the guide said, fresh oregano would be replaced with a dried alternative. On January 11, the company introduced blanching of produce: Chipotle’s lemons, limes, onions, avocados, and jalapeños would now be plopped into 185-degree water for five seconds—a so-called kill step that eliminates pathogens. By January 16, bags of the precut lettuce and bell peppers, now chopped at central kitchens with samples tested in laboratories, arrived at all Chipotle restaurants.

Internally, however, Ells and Moran soon began doubting the very food-safety practices they were touting, namely the high-resolution testing. They tell me that the taste of the lettuce and bell peppers suffered markedly due to being prepared off-site. “The quality wasn’t what it was,” Moran says. “Customers thought we went to iceberg lettuce. That broke our hearts.”

Some involved with the company also felt the mechanics of adopting the sampling regimen were too daunting. “We were practically testing every piece of meat that came into the door!” recalls Chuck Nalon, president of Ed Miniat, one of Chipotle’s largest centralized kitchens. “We knew, and they did too, that this wasn’t our future.”

In the short term, the high-resolution testing enabled the company to better profile whether its suppliers were exhibiting acceptable levels of bacterial control. This testing rejected a significant amount of food in the company’s supply chain, which resulted in the suspension of a few suppliers. Chipotle confirms these actions.

When I ask Arnold whether the high-resolution testing revealed any dangerous pathogens—such as, say, E. coli 026—at its suppliers, he clarifies via email, “High-resolution testing doesn’t identify pathogens.” According to three food-safety experts, high-resolution testing is capable of identifying specific pathogens; Chipotle, however, implemented a system with a faster turnaround time that was essentially a pass-fail version of this test. If a batch of beef failed to pass Chipotle’s quality standards, the company only knew that it failed, but not why. “[Faster testing] does make a difference when you have fresh products,” says one outside food-safety expert who spoke only on the condition of anonymity. “You don’t want it to go bad waiting around for the perfect test result.”

According to two sources, one of the other upsides of Chipotle’s pass-fail system was that it came with a different disclosure requirement. “If you are preparing produce at the central-kitchen level and you do a test whereby you determine the presence of… salmonella or E. coli 026 or 0157, you are legally required to report that to the FDA,” says one industry expert who works with Chipotle. Arnold affirms this distinction, and acknowledges the pass-fail system did not require regulatory notifications, but he stresses, “Did we select the high-resolution [pass-fail] testing because of its lack of regulatory triggers? No.”

In early February, Ells and Moran hired Jim Marsden, a Kansas State University meat scientist, as the company’s new executive director of food safety. Marsden eventually rolled back Samadpour’s high-resolution DNA-based testing. “I don’t think Steve or Monty or anyone else had the slightest idea what the difference was [between pass-fail and specific-pathogen testing],” Marsden says. “It sounds all scientific—the word DNA sounds good. I think they just took the recommendation from the consultant [Samadpour].” (Samadpour says he cannot comment on this particular situation but generally disagrees with Marsden’s assessment. “The testing method and choices of other test systems are always discussed with clients, and they get to choose which approach is the best for them,” he explains.)

Marsden started shifting Chipotle’s focus to “interventions,” safety measures that assume contaminated food could sneak into the supply chain. This approach involves instituting a series of kill steps to prevent pathogens from reaching your fork. Samadpour had already introduced produce blanching; Marsden set about exploring additional safeguards.

Central kitchens took over precooking steak in March. It would now be reheated at the restaurants. The company considered having its chicken, which constitutes 55% of sales, precooked at these outside facilities but concluded it wasn’t logistically feasible.

Some observers wondered if the company was overreacting, given that it didn’t even know what caused the E. coli outbreak. Marsden, though, saw this moment as a fresh start. “The opportunity is that we fix everything—go through the entire list of ingredients and food products and address all the possible vectors of contamination,” he says.

All the changes alarmed many employees. On a practical level, if more preparation was happening in central kitchens, some feared their labor would no longer be needed. They were not wrong. “We started cutting their hours,” says a former general manager. “People took pride in cutting bell peppers and lettuce. When we took that away, morale started getting lower.” (Hartung, the CFO, tells me that the company did not reduce its hours as much as it could have given how steeply same-store sales declined.)

“It’s not fresh anymore!” says a source familiar with Chipotle’s food-safety program. “Sooner or later someone is going to say, ‘What’s the difference between Taco Bell and Chipotle?’ The difference is you pay much less at Taco Bell. The tomatoes, the lettuce—they’re all coming from the same place. Taco Bell is [precooking] your meat and now Chipotle is too. There is no distinction.”

Chipotle leaders scoff at that notion. As Arnold puts it, “We do share some suppliers with other large restaurant companies. That does not mean we use the same ingredients or cooking methods.”

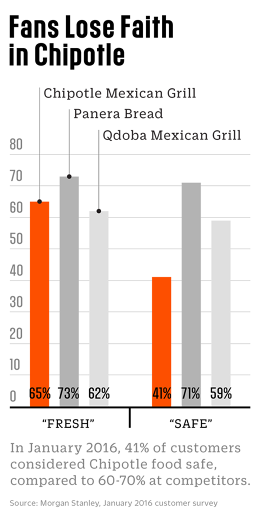

Because Chipotle built its image around the high quality of its food, its brand was now susceptible to questions of trust. Convincing customers that Chipotle was still better than the rest—and getting them back into restaurants—was the next big hurdle.

Chapter 4: A Marketer’s Dilemma

Wooing back the faithful.

In the cutthroat fast-food industry, Chipotle has differentiated itself by rejecting the traditional tactics of its rivals. Along with investing heavily in the freshness of its ingredients, the company avoided pandering to its audience with limited-time stunts like the McRib or KFC’s chicken-encased Double Down sandwich. Other chains peddle Happy Meals and PlayPlaces, dollar menus, and blockbuster-movie tie-ins. Chipotle never even gave in to number-coded meal items (“I’ll have the No. 3, please”).

The mastermind behind all this was Chipotle’s chief marketing officer, Mark Crumpacker, yet another college friend of Ells’s. Crumpacker, who ran a branding agency before joining Chipotle in 2009, was careful not to let these types of gimmicky initiatives drive the company’s direction and identity. “It’s the crack of marketing,” he told Fast Company in 2012. “Once you’re on it, it’s really, really hard to get off.”

Instead, Crumpacker released animated films promoting Chipotle’s food ethics, commissioned novelists such as Toni Morrison and Jonathan Safran Foer to write short original pieces to feature on food packaging, and launched a “food, music, and ideas” festival called Cultivate. The results gave Chipotle a creative, ethically conscious aura—and won Crumpacker and the company a mountain of advertising awards, which line his office’s shelves. It also enabled Chipotle to flourish without the conventional high-cost investments in fast-food advertising. In 2015, the company spent just $69 million on marketing, or 1.5% of its sales. McDonald’s spent $718 million, or 2.8% of its revenue.

In the aftermath of its food-safety crisis, however, the company realized that this preexisting playbook was too limited. They needed to get customers back into the restaurants, and fast. The hope was, if lapsed customers just sampled Chipotle’s burritos and tacos again, they would remember why they loved them, and the company’s momentum would resume. But given Chipotle’s marketing philosophy, it couldn’t merely adopt conventional fast-food tactics. When Jack in the Box experienced its 1993 E. coli crisis, which tragically killed four children, it nearly went bankrupt. Then it slashed the price of almost all its menu items, permanently offering its signature Jumbo Jack burger for just 99 cents, and within three years was back on track. Its recovery was further spurred by a series of aggressive, irreverent TV spots featuring the introduction of “Jack,” the company’s “CEO.” The mascot, a suit who’s a pinheaded clown, was an instant smash. In one 1994 commercial, he boasts, “Jack’s back”—and then is shown literally blowing up the company’s board of directors.

Chipotle’s options were narrower. Among other things, a discounted menu wouldn’t support the high cost of Food With Integrity and could damage the company’s premium “fast casual” brand positioning. Hartung says Chipotle was “careful not to jump on that treadmill… [where] you’ve got to wring costs out of your food… to offer things at 99 cents or $2.99 and market the heck out of it.” Nor could Chipotle, with its anti-McDonald’s bent, introduce some clown spokescharacter (let alone one that blows up its board). Chipotle’s E. coli crisis was different from Jack in the Box’s: Nobody had died, for one, but Jack also never had to deal with social media outrage. Nor did it promote its burgers and fries as a better-for-the-planet alternative.

What executives settled on was an aggressive direct-mail blitz in early 2016: Chipotle sent coupons for a free meal to 20 million households to encourage them to return. The company also introduced a $50 discount for catering orders of at least 20 burritos during the Super Bowl. The idea, Crumpacker says, was to rekindle that communal dining experience and “overcome the veto effect” of any one person steering a group of friends to a different restaurant.

Whatever progress these initiatives may have been making, though, was lost when another norovirus incident hit in early March—this time in Billerica, Massachusetts. The company promptly closed the restaurant after several employees reported symptoms; no customers were infected, yet it appeared in the news as if another outbreak had occurred. In an earnings call in late April, the company reported that sales had plunged 29.7% for the quarter. While 17.5% of the free-burrito coupons had been redeemed (and a similar mobile offer had a 67% success rate), it wasn’t enough. Executives on the call talked up plans for additional giveaways worth more than $40 million. Crumpacker also trumpeted a plan under way for “the largest media spend in our history,” which he said “reinforces our commitment to responsibly raised ingredients cooked using classic cooking techniques.” On the horizon was another initiative to revive the faithful: A few days later, Chipotle would host one of its signature Cultivate festivals, in Scottsdale, Arizona.

Chipotle executives will tell you that Cultivate is Ells’s Food With Integrity philosophy brought to life. It’s a venue to advocate for the strong public stances the company has taken against genetically modified foods, factory farms, and many other hot-button issues—all in a family-friendly environment with young bands and live cooking demos.

The gates at the WestWorld fairground in Scottsdale open at 11 a.m. on a cloudy April Saturday morning, and when I arrive 20 minutes early, there’s no sense that any of the bad news of the past six months has hurt enthusiasm. The line of people waiting to get in already stretches a furlong into the parking lot.

Inside, families stroll amid dozens of white pointy tents that line the trodden-grass field. Bales of hay and sacks of grain dot the mountain-framed landscape. Strips of chicken and fajita veggies sizzle on the Chipotle grills. Sure-to-be-carded boys and girls race to the tasting tents where beers from Grand Canyon Brewing Company and other craft brewers sell for $6 a cup. Food Network personality and acclaimed chef Aarón Sánchez prepares for his onstage culinary demo. The pop band Echosmith is scheduled to perform later in the afternoon.

People here are happy. The only reminder that Chipotle is in the middle of a crisis is the addition of a “Food Safety Information” tent. It’s by far the least popular area of the fair. For much of the day, the eight staffers stare blankly at their visitor-free surroundings. When I ask a dad pulling his son in a blue roller-wagon what they’re telling people, he jokes, “You know, things like, ‘We won’t kill you anymore!’ ”

Today’s attendees are Chipotle’s most forgiving fans. “My husband is a cook, and [these outbreaks] could happen to anyone,” one mother says over tacos as her kids play on a picnic blanket. “They took responsibility for what happened.” A slew of parents tell me the food-safety issues don’t diminish their affinity for Chipotle whatsoever; they still love the company’s ethical food and affordability.

Chipotle reinforces its message everywhere. Big signs placed throughout the grounds prominently display Chipotle “FACTS,” such as the one by the porta-potties that reads, “Nope, Chipotle is not owned by McDonald’s.” (The Golden Arches was a major investor in the early aughts but fully divested by the time Chipotle went public in 2006.) A nearby merchandising tent sells T-shirts adorned with the Chipotle logo and phrases like “Family Farmed” and “Locally Grown.”

There are even a handful of spots where you can “Learn Your Way to a Free Burrito.” The tour begins at the “Chipotle Cinema,” where under one of the tents, a large projector screen shows Ells chopping onions and cilantro as he makes guacamole from scratch at a Chipotle restaurant. Next is the “Fresh vs. Processed” food exhibit, followed by the display articulating the downsides of GMOs. Inside two shipping containers housing the “Factory vs. Farm” presentation, models of frightened-looking pigs are shown raised in claustrophobic confinement; a tall plastic tube chock-full of oversize capsules is stamped livestock antibiotics. (Signs warned that the experience “may be disturbing for children or anyone who is particularly sensitive to animal suffering.”) The folks here eat it all up, including the promised free lunch.

Around 4:30 p.m., threatening clouds roll in and people dash to their cars as thunder rumbles, lightning flashes, and rain pours down. Chipotle is forced to end the event several hours early. Exiting the parking lot in the storm becomes a horrendous, infuriating crawl. As one attendee tweets under the hashtag #ChipotleCultivate, “This is worse than E. coli poisoning.”

Chapter 5: Farm-to-Table Casualties

Happy pigs, unhappy farmers.

A week after Cultivate, I visit Polyface Farms in Swoope, Virginia, a three-hour drive from Washington, D.C. Polyface, which has been a Chipotle pork supplier since 2007, is one of the places that gives credence to Chipotle slogans like “Family Farmed” on T-shirts at Cultivate.

Past winding roads and a small bridge, I find owner Joel Salatin, arguably the world expert when it comes to responsibly sourcing pork (his latest book, published just four days earlier, is titled The Marvelous Pigness of Pigs), lugging planks of wood across a green field. He’s dressed in a felt outback hat, collared shirt, Wrangler jeans, and muddy boots, with suspenders tucking in a slight belly. I ask if I’m interrupting his work. “Not a beat!” he says with a wide grin and a high-pitched chuckle I’ll hear again and again.

We pile into his pickup truck and putter around his farm under a blue sky. It’s so idyllic, it’s almost cliché. Cows and chickens roam on shoulders of fresh glistening grass. An overdue shower recently made its way to the Shenandoah Valley and the petrichor wafts through the truck’s rolled-down windows.

This is the pastoral image Chipotle conveys to customers. By partnering with local farmers like Salatin, Chipotle positioned itself as the antithesis of McDonald’s and the industrial-food-supply complex, while gaining the blessing of a cadre of foodie evangelists such as the prominent writer Michael Pollan, whose best-selling 2006 book, The Omnivore’s Dilemma, celebrated Salatin and his unique approach to animal husbandry. Pollan has said that Chipotle is his favorite fast-food chain.

Ells’s first steps toward Food With Integrity began in 1999 when he read about Bill Niman, who shares many of Salatin’s agricultural philosophies. Ells visited Niman Ranch in Iowa and became enamored of its approach to responsibly raising pigs. Together, Ells and Niman also toured the conventional hog farms and slaughterhouses where the majority of Chipotle’s pork was then coming from. “These were not farms, they were confinement operations, factories,” Ells recalls. “It was really superbad. I knew that I didn’t want my success or Chipotle’s based on that kind of exploitation.”

Chipotle started buying pork from Niman Ranch, then a collective of around 70 like-minded family farms. “It wasn’t about the cachet,” Niman tells me. “Steve was… I don’t know if ‘compulsive’ is strong enough. He was demonic about his food quality.”

If Ells was going to use Chipotle to upend the traditional fast-food model, working with single-location farmers like Salatin—Polyface was just 550 acres at the time—was the next logical step. Salatin says that he and Ells “got along great, and he said he wanted our pork,” recalling their handshake deal after they met in 2006.

Not everyone at Chipotle was sanguine about working with Salatin. Polyface’s pork was costlier. And, unlike Niman, Salatin refused to let his pork be shipped to one of Chipotle’s central kitchens. “They were going to take our pigs from here, put them on a backhaul truck to [a central kitchen], cook [the meat], and then bring it back here. I said, ‘Come on, guys! Talk about a carbon footprint! That’s crazy,’ ” Salatin says, drawing out the last word to indicate how much he disagreed with that plan.

Chipotle’s marketing team pushed for the deal, while Chipotle’s quality-assurance team was hesitant: For one thing, Salatin did not own a refrigerated truck. “[They] were going apoplectic,” he chuckles. Salatin and Chipotle eventually worked out a system that satisfied safety procedures, and after outfitting a restaurant near the University of Virginia so they could cook carnitas in-house, Chipotle began offering Polyface pork on its menu. (They later did the same at a second restaurant near James Madison University.)

It was a huge hit. “We taught the kids [at the restaurant] how to do old-school braising. Like really sear the pork, dry-rub it, roast it off in the oven, and shred it,” beams Joel Holland, a veteran executive chef who worked directly with Ells at Chipotle. “It started getting a buzz in D.C.!”

Chipotle wasn’t shy about publicizing its local-farmer relationships. When ABC’s Nightline profiled Ells in 2009, he arranged for the segment to be shot at Polyface. The following year, when Oprah Winfrey approached Chipotle about an interview, Ells suggested to a colleague that they shoot the segment at a cattle ranch. The problem? It was the dead of winter. “There were probably 22 inches of snow on that land,” this colleague recalls. “Steve was like, ‘Well, can we plow the snow and still film in one of the green pastures?’ ” (Ells does not recall making the comment, but says that if he did, it was in jest.) Winfrey interviewed Ells in her Chicago studio.

Around this time, Chipotle was also expanding its “local growers program,” the company’s commitment to sourcing some of its seasonal produce from within a certain mileage of its restaurants. This distance was then defined as within 200 miles of its locations, but the company has since increased that threshold to 350 miles. By 2010, the company was working with roughly 50 family-owned farms to purchase some 5 million pounds of its lettuce, red onions, tomatoes, and other items. “Our commitment to serving produce from local farms and other sustainable sources is one of the ways we are changing the way people think about and eat fast food,” Ells said at the time. By 2015, Chipotle increased its orders with these suppliers so they now provided more than 30 million pounds of vegetables, which the company claimed comprised about one-tenth of its produce purchases when they are in season.

Local sourcing has been among the casualties of the E. coli outbreak. Ells, citing safety concerns, says the company has cut its dependence on these local growers—by as much as 83%. Curious how the company determines what sources count as “local,” I ask whether that one-tenth seasonal produce figure could include Taylor Farms (one of the world’s largest lettuce suppliers) if there’s a Chipotle restaurant within 350 miles. Ells says, “I don’t think so,” and Moran adds that the program is not really for large producers and promises to get me a specific answer. Arnold ultimately confirms that Taylor Farms could qualify. “Correct,” he writes via email. “Proximity is the determining factor for our local produce program, not farm size.”

Salatin tells me that Polyface still only provides pork to those two Chipotle restaurants in Virginia college towns. The company, he says, has discussed expanding his pork to 10 restaurants, but it has been “stymied” by its E. coli issues. Chipotle says that it never set a firm expansion goal and states that the issue is more complex. Before the outbreak, Chipotle purchased between 550 and 600 pounds of meat weekly from Salatin. In the immediate aftermath of the crisis, it sometimes bought as little as 100 pounds. Today, Chipotle’s weekly order hovers between 300 and 400 pounds. As a result, Salatin says that he has 9,000 pounds of pork “in the freezer that was supposed to go to [Chipotle] but that they haven’t taken since this debacle occurred. We got pigs in the pipeline, and we can’t afford to keep them on the hoof. For a small business like us, it’s actually very economically devastating.”

He’s not the only one. For some of these smaller purveyors, which substantially ramped up production to meet Chipotle’s demand, the lost revenue has materially affected their businesses. “Chipotle went around to all the suppliers and they just tore those places apart looking for [traces of] foodborne illness,” one supplier tells me. “Everybody came up clean, but that doesn’t mean they weren’t damaged [from the lost sales].”

Salatin remembers his friends in the farming community warning him of this possibility five years ago. He would give talks to thousands of farmers each year, and “they started coming to me everywhere I travel, saying, ‘I called Chipotle and they won’t even return my calls. They don’t want local food! They’re just using you as a poster child for publicity!’ ” Salatin remembers.

He had hoped Chipotle might one day source 100% of its pork from Polyface-size suppliers, but it was clear even then that this was an unlikely outcome. When he confronted a Chipotle meat executive around that time—telling him, “I love you guys, but I don’t want to be used here”—he was told the company was doing its best to source more food locally but that it was an extremely complicated process given all the associated logistics and costs.

“I’m sure Joel [Salatin] wasn’t happy with how it played out. I wasn’t, either,” says Holland, the former Chipotle chef. “Did marketing get what they needed out of it [and move on]? I don’t know. Inside of me, I want to believe it just got short-circuited for business reasons. Where is it marketing? Where is it real? Where is the transparency?”

Chapter 6: “Smoke and Mirrors”

What “Food With Integrity” means now.

Chipotle’s efforts to revive its sales accelerated in late June. The company introduced a summer-long rewards program, called Chiptopia, which has already attracted several million sign-ups. It launched a branding campaign centered around a heartwarming animated short film titled A Love Story, which played on more than 10,000 movie screens. And it added a new protein, chorizo, to Chipotle’s menu in select markets. “That stuff works when people say, ‘Oh, something new, I want to try that,’ ” says Crumpacker, the marketing impresario. “That’s a page we pulled out of the traditional fast-food playbook.”

Around this time, the company reported its second-quarter earnings. Chipotle fell short of Wall Street’s expectations, but there were signs of recovery: They returned to profitability and its quarterly same-store sales, which were down 23.6% year over year, narrowed their decline when compared with Chipotle’s first-quarter results when sales dropped 29.7%.

But just as Chipotle leadership began to feel some sense of momentum, an unexpected crisis embarrassed them: Crumpacker was indicted for cocaine possession leading into Independence Day weekend. He surrendered to police and faces seven counts of drug possession; Chipotle placed him on leave, and he checked into rehab.

Two weeks after the news of Crumpacker’s arrest, I travel to New York to meet with Ells at Chipotle’s Union Square office. These recent events are an awkward backdrop to my visit, but when Ells strides into a conference room to greet me, he’s poised and upbeat, dressed in a navy blue Lacoste polo and crisp khakis. He says he wants to go to a room where there’s more sunlight and briskly escorts me to his corner office (which is next to Crumpacker’s now dark and unoccupied one). It’s a minimalist space; an iMac hides in a small nook across from his diploma from the Culinary Institute of America.

We sit at a mahogany table over blueprints for a new restaurant, and Ells tells me that what’s top of mind for him is instilling safety into the company’s mind-set. “[It’s] the hardest thing to put into place… Cultures are developed over a long period of time,” he says. “It has to be deeply instilled, much like our people culture or our food culture. We’re coming at this from all angles: from the supplier side, the procedures in the restaurants, things through the distribution system, training, and auditing.“

The culture Ells is most comfortable talking about is food. I ask whether the company is still living up to its Food With Integrity promise to consumers and how Chipotle precooking proteins like steak in central kitchens fits in. Ells says it’s “misleading” to call the steak “precooked.” Rather, he says—his eyes peering over his narrow-framed glasses—it’s “sous-vide.” This is the French cooking term for immersing food, sealed in a bag, in a low-temperature water bath to heat it slowly and more evenly. “This technique was used by many chefs and still is because you can precisely control the characteristics of meat and achieve a certain kind of tenderness,” Ells says. “I’d say the steak is [now] more tender. It actually improves it.”

When I bring up Chipotle’s blanching of produce, Ells says it’s more akin to “tomato concassé,” which is a “French term for when you blanch the tomato, cool it, and peel the skin off. It’s part of the world of classic cooking techniques.” I feel as if I’m being schooled by a judge on a cooking show (which, incidentally, Ells once was, on NBC’s short-lived America’s Next Great Restaurant).

Holland, the former Chipotle chef (who still reveres Ells), suggests that Chipotle is now selling “smoke and mirrors,” a kind of “doublespeak” that implies its new food-safety practices somehow count as classic cooking techniques. “The moves they’re making now kind of rebut everything they’ve done in the past,” he says.

Speaking on background, even one of Ells’s close friends agrees with this assessment. “One of the unfortunate consequences [of the crisis] is that this wonderful fresh food, which comes with a risk, is going to be precooked, pasteurized, double- and triple-washed, all the things that you wouldn’t do [at home],” the source contends. “Would you rather eat [real fresh food and] take a chance on getting a case of the shits? Or would you rather have your food precooked and every possible intervention done to [it]?”

When I relay this assessment to Ells, he says, “Nothing could be further from the truth.”

What’s dismaying to those who know Ells well is that he has always fought to do what he thought was right to improve the food Chipotle serves, even when it didn’t benefit Chipotle’s bottom line. He once spent a year and a half cycling through prototypes for an egg cooker so Chipotle could offer breakfast burritos. “We chased that to no avail and spent who knows how much money,” recalls a former executive who worked intimately with Ells and had knowledge of the failed effort. Once, Ells wanted to wedge a Jamba Juice–style blender operation into every Chipotle restaurant so workers could freshly squeeze limes, even though its kitchens only consume a half-cup of citrus juice per batch of guacamole. That didn’t work out either. At Ells’s insistence, many stores boast a custom-built $6,000 grill, though the inside joke among some executives is that despite all the fancy kitchen improvements Ells added or attempted over the years before the crisis, the burritos pretty much taste the same as they did 15 years ago.

But others will argue just as vehemently that his creativity and knack for tapping into a je ne sais quoi is what made Chipotle so special. “The thing with Steve is, every now and then you’d get one [brilliant idea] and it might turn out to be the next big thing,” says the former executive. Ells says, “I certainly could’ve made a lot more money buying cheap ingredients and people might not have been able to tell the difference. That was never a part of the calculus. It was not part of my DNA.”

In balancing food safety with Food With Integrity, Ells admits that the pendulum swung too far toward more conventional methods of fast-food production immediately following the outbreaks—for the sake of Chipotle’s customers and its business. Now, though, Ells says that the company is working to correct certain overreactions. He promises to recommit to the local growers program and believes Chipotle will return to the precrisis number of independent suppliers in 2017. He says Chipotle has moved more ingredient preparation back into its restaurants, including whole heads of lettuce and bell peppers.

How can Chipotle pull this off without risking another outbreak? After all, if another one were to happen, even the rumor of one, “it’d be really bad,” Hartung says. “Our recovery has been fragile so far.”

One new tool in the Chipotle arsenal: On June 1, the company rolled out The Black Book—a revamped version of the Daily Food Safety Checklist—which ushers in stricter in-restaurant safety protocols, including 10 “critical control points,” ranging from additional personal-hygiene checks to more detailed temperature logs. It also introduced the role of food-safety leader, who is the most senior manager on duty and makes sure all these mandates are met.

The Black Book’s changes demand considerably more audits; its Food Safety Leader Guide, for example, features 32 bullet points on hand-washing and disposable-glove procedures alone. “We believe that… achieving our goal of being the industry leader in food safety is within our reach,” Ells and Moran wrote in introducing the Black Book.

Jim Marsden, the executive food-safety director, says the company has also added a number of pasteurization methods, including “high-hydrostatic pressure processing (HPP),” which essentially sterilizes food such as chorizo by blasting it with 87,000 pounds of water pressure for three minutes. (This practice takes place at specialized, off-site facilities that can support these 85-ton HPP machines.) Marsden boasts that Chipotle is now an industry leader in the practice, though, he admits, it’s long been used for “things like sliced turkey breast, prepared salads, usually foods that are in the ready-to-eat category.” An FDA report on HPP says the process results in changes that are usually “undesirable because the food will appear to be processed and no longer fresh or raw.” Arnold says that chorizo has been well received. Chipotle has since rolled it out to restaurants nationwide.

Marsden also instituted his own testing approach, replacing Samadpour’s system with one that centers on “routinely” verifying the efficacy of Chipotle’s intervention requirements. Rather than having suppliers take more frequent samples of raw beef, for example, they can now test at far fewer intervals because the meat is cooked; they’re primarily doing this to ensure that kill steps, such as the sous-vide process, are working properly. As with Samadpour’s program, there are complicated pros and cons to this system, but as one neutral food-safety observer says, “If you’re in a courtroom and you listen to both sides of the argument, it’s hard to say that anyone is 100% correct. It’s all wrapped up in a lot of academic in-fighting and politics.”

Ells remains adamant that nothing has changed with the food Chipotle serves. All these new measures are predicated on his belief that it is now not only safer but also tastier and fresher than ever. Proteins like steak, he argues, are “marinated just like we’ve always marinated” them at the restaurant: The sous-vide meat arrives from the central kitchen and “looks raw and very red” before it is cooked on-site. (When I ask a kitchen worker at a restaurant if Chipotle’s steak has changed, he matter-of-factly responds, “Yeah, it’s precooked now.”) “It might be different, but it’s still delicious,” Ells says. “We want our cake and we want to eat it too!”

The comment reminds me of A Love Story, which has garnered 60 million views. The film seems to reflect the company’s own angst regarding its current state. The ad, which went into development six months before the crisis began, depicts two neighborhood kids who build their rival sidewalk juice stands into fast-food empires. The result is a dystopian future where their food is manufactured by machines on assembly lines, and new menu items and buy-one, get-one-free deals lead to huge profits. The main characters eventually leave it all behind to start a taco truck where they cook food with fresh ingredients and, of course, love.

The point of A Love Story, like two previous award-winning shorts, is that Chipotle is not McDonald’s. But it’s impossible to ignore a different subtext now given all the change the company has undergone: Is Chipotle in danger of becoming the evil fast-food chain?

I decide to put Ells on the spot. I ask if I could have a list of every Chipotle supplier. Ells says he’s never heard such a request before but that he’d have his team look into it. He tells me that the reason the list isn’t made public has nothing to do with trade secrets. (Later, Arnold explains that he can’t share a list of suppliers with me for “business competitive reasons.”)

Would Ells at least share the names of Chipotle’s beef suppliers in Australia? “I don’t know the name offhand,” Ells responds. “It’s not like a brand that you would buy at the grocery store.” (Chipotle sources some of its beef through JBS Australia, a giant of the meat industry that also works with McDonald’s.)

I also ask if I can visit Chipotle’s central kitchens, the ones that work with McDonald’s, Subway, and Pizza Hut.

To my surprise, Ells agrees.

Chapter 7: Is This Classic Cooking?

Inside a 200,000-square-foot food factory.

Ed Miniat, one of Chipotle’s three largest central kitchen partners, is headquartered in the Chicago suburb of South Holland, Illinois, near a long stretch of strip malls. Once inside this 200,000-square-foot facility, I am greeted by Miniat president Chuck Nalon, and he and I don rubber boots, parkas, lab coats, two sets of gloves, latex sleeves, earplugs, protective eyewear, red hairnets, and hard hats. We slop through a pool of antibacterial foam spraying at the entryway to sanitize the soles of our boots—”a nice car wash!” jokes Nalon, a burly salesman whose own hard hat is painted to look like a football helmet from his alma mater Purdue. “This is where it all starts.”

The scale of Miniat’s operation is immediately overwhelming. Nalon guides me through warehouse-size rooms filled with yellow vats of raw chicken and hundreds of workers, who are decked out in the same safety gear as we are. They’re running massive metallic machines, including “The Injector,” a hulking apparatus with more than 975 parts designed for meat “augmentation.” (“Chipotle doesn’t use the Injector,” Nalon clarifies, though other Miniat customers do.) The highly industrialized atmosphere calls to mind visions of the boiler room on the Titanic, with all of Miniat’s pipes and blue lights flashing everywhere, along with its ceaseless clangs and clanks, whirls, and whirrs.

Miniat processes roughly 500,000 pounds of beef and pork each week for Chipotle, and it’s now ramped up production of the chain’s sous-vide steak. Nalon first takes me to the line that prepares Chipotle’s barbacoa beef. Butchers occupy 22 stations, and they trim shoulders of any excess fat and gristle. A small computer screen at each station monitors each worker’s meat yield; every chunk of protein is weighed before it slides down a conveyer belt. It eventually ends up in a huge, cement mixer–like machine that swirls it around in a blend of adobo paste, water, and garlic.

We go through several massive doors—which slide open when Nalon tugs an orange cord hanging from the ceiling—to a space where I can see the sous-vide process Ells mentioned. Forty-eight tubs, each the size of a dishwasher, are filled with 180-degree water that slow-cooks bags of meat for six and a half hours before they’re chilled for another three. Finally, I watch workers, including one with a pitchfork, shovel the finished meat into five-pound portions, before it’s sealed and later boxed and shipped to Chipotle’s restaurants.

“Isn’t it beautiful? And it smells good!” says Nalon, who echoes Ells when he mentions how these are all just “classic cooking techniques. This is your [household] kitchen times 25,000. There’s no other way to pull this off.”

The modern and hygienic facility does smell delicious, and it is difficult to imagine how Chipotle could decentralize its entire food operation to more than 2,000 local restaurants. “There’s nothing mysterious about what we’re doing, and everything can be easily explained,” Nalon says. “The whole goal is to make good food. The average person should be able to go, ‘I never dreamt this is how it works behind the curtain, but I get it.’”

That said, Miniat is the only central kitchen that allowed me inside—only at Ells’s request—and even then, the company doesn’t allow photographs of its facilities. The fact is that Miniat, like Chipotle’s other major central kitchens OSI and Ready Foods, is a factory—not the mechanized sweatshop in A Love Story, but it’s not home cooking either. Sanitizing this place, for example, requires the “Miniat Elite,” a 64-person team, which, each night over the course of seven hours, rinses and washes every single inch of the facility (including all 975 disassembled parts of the Injector) and cleans up 12 tons of goopy carcass remains, grease, and oil, using 52,000 gallons of water in the process.

Although McDonald’s relies on a similarly centralized model, Chipotle supporters contend that the chain has higher-quality ingredients and preparation standards. In their first meeting to discuss pricing, in 1998, when Chipotle had just 15 restaurants, Nalon recalls “Steve’s face getting more and more contorted” as Nalon explained how to make the recipes cheaper by “adding starch, injecting [meat] with marinade,” and so forth. “I marched down the list of all my food-science options,” he tells me, and “Steve said, ‘Promise me you’ll never do anything like that to my food.’ ” Nalon isn’t allowed to discuss Miniat’s other clients, but he does acknowledge they utilize his kitchen differently than Chipotle.

Back in Nalon’s office, where an old menu sign from a Chipotle restaurant hangs on the wall opposite a Food With Integrity poster, I ask whether Chipotle could simply move all its food preparation to central kitchens like this one. After all, if the food can taste just as good, why wouldn’t they, especially if it’s safer? “Hmmm, and still be Chipotle? Not everything, no,” Nalon says. “I love the fact that they do what they do in those stores, because it is totally unique. You could do everything in central kitchens, but I don’t think that’s exactly what they want. They want to bring as much freshness and as much cooking as they can to the stores. But [some of these items] really need to be done with somebody like us.”

Chapter 8: People Who Matter

A proud CEO, “the crème de la sour cream,” and what $9 per hour buys.

If Ells is the food person at Chipotle, co-CEO Moran is the people guy. It’s his task to drive the company’s employees to safely prepare, assemble, and serve Chipotle’s food at a pace that can sometimes exceed 350 transactions per hour. “[Without] dramatic improvements in throughput,” Moran told investors before the outbreaks, using the restaurant-industry term for serving customers quickly, “we would not be able to achieve such phenomenal same-store sales.”

Moran has been a trusted confidant to Ells since Chipotle started. Moran served as Chipotle’s outside general counsel before joining in 2005 as COO to help scale operations. Following the company’s 2006 IPO, Ells increasingly relied on him, and when Ells decided to move to New York full-time in 2008, Moran essentially took over the company’s Denver headquarters.

By the time Moran was elevated to co-CEO in 2009, the company had moved to a new office on Denver’s Cherry Creek River, where the mood became more “corporate” and “tense,” sources say. Dogs were no longer allowed, and executives initially moved to an area locked to most staff. “It was the weirdest thing,” says a former longtime employee who worked closely with Moran and Ells. “I mean, you had to be buzzed in! The office became so sterile and cold. Monty ran things like a law firm.”

Moran’s ascendancy at Chipotle has coincided with an increased rigor (some would say bureaucratization) in the company’s restaurant culture. Restaurants are graded on the “Four Pillars” of throughput, such as “Aces in Their Places,” which requires that crew workers are ready in their prime positions at the exact second their shift begins. In fact, the cameras above the line in all Chipotle’s restaurants aren’t only for security; managers and internal analysts access these live feeds either weekly or monthly for surprise, 15-minute “visual audits” to gauge how well teams are executing the Pillars during peak hours. “Everyone would see these audit results, including Steve and Monty,” recalls a former operations executive. “You did not want to be at the low end.”

Chipotle’s unrelenting culture has sometimes embroiled the company in controversy. This past summer, 10,000 employees filed a class-action lawsuit against Chipotle accusing it of not paying them for all the hours they worked. In mid-August, a court ordered Chipotle to pay a former crew member of a Washington, D.C., restaurant $550,000 for workplace discrimination. A jury found that her supervisor had, among other things, restricted bathroom breaks and access to water for this employee, who was then pregnant. (Chipotle maintains that its actions in the Washington case were legal, but does not plan to appeal.) When I ask Moran about all this, he says, “Do we hire people who make mistakes? We sure do,” noting that the company will recruit 60,000 people in the next year. “I spend all of my time making this culture the very best it can be.”

Moran prides himself on engineering the company’s “Restaurateur Program,” which he conceived in the wake of the 2008 financial crisis and considers central to the company’s success. The program is designed to imbue workers with the long-term ambition of becoming “Restaurateurs,” a sort of certified-excellent general manager position, which comes with a higher salary, a company car, stock options, and other bonuses. Moran calls the GM “the most important person in the company,” because “if you’ve got excellent GMs, you’re going to have wonderfully safe food, delicious food, and a great customer experience. If you don’t, you won’t.” Restaurateurs, then, are the “crème de la sour cream” of all GMs, as Chipotle phrases it in recruitment materials.

The program incentivizes managers to evaluate employees based on whether they are “top performers” or “low performers.” To even get a shot at the restaurateur title, you have to work your way up—often starting at crew member—and train top-performer replacements as you advance. “A manager who leads in an enlightened way creates teams of top performers who are empowered to achieve real standards,” says Moran. “Those are magic words around here.”

Chipotle’s upwardly mobile structure increases service speed and eliminates “loads of bad habits,” says Moran, who, along with Ells, would personally approve restaurateurs based on intense in-person assessments. When a restaurateur would be ready for review, one of the CEOs would make a trip to his or her restaurant, scour the place for red flags, and even individually interview each crew member. (As the company has grown, other C-level executives also perform evaluations.)

According to more than a dozen sources who experienced or witnessed these reviews firsthand, this became a “dog-and-pony show.” If Ells showed up in a bad mood, a candidate’s odds would be especially slim; several sources relate stories of him ripping into prospective restaurateurs for mistakes as trivial as, say, finding leftover grains of rice on a tabletop or using two different types of lightbulbs in the ceiling fixtures. If Moran, who is friendlier, conducted the visit, he’d usually base his evaluation on the temperature of the room—how many customers are smiling, the enthusiasm he senses from crew members. Moran, though, could be just as demanding as Ells, and once nearly ended an otherwise perfect visit after stumbling upon “easily the dirtiest fucking pans I’ve ever seen.” Moran acknowledges, “If we see things that are dirty, that would be one of the many things we would look at. But no, we’d never say, ‘There was rice on the table, you’re not a restaurateur.’ ”

The restaurateur program has reinforced a culture where “low-performer” employees are acceptable collateral damage. At the company’s 2012 all-managers meeting, for example, Moran asked the hundreds of attendees for a show of hands if they had low performers on their teams. Most raised a hand. “Why are you letting these people stay on your team?” two attendees recall Moran saying. “If they’re not doing a good job, just fire them. We don’t need them.” “Those words—low performer—were weaponized at Chipotle,” says a former team leader, who regretfully recounts meetings among managers where they would viciously appraise crew members. “You’d put someone’s name on the whiteboard and [a manager] would growl, ‘Aarrgghh, no! Low performer! They’re no good!’ Once they were [deemed] low performers, their careers at Chipotle were torpedoed whether they knew it or not. Everyone was disposable.”

Perhaps that helps explain why crew-level turnover is three times higher than manager turnover, which itself is a challenge: Out of every 100 kitchen managers Chipotle promotes, only 25 of them remain on staff after 12 months. Despite the churn, “there was an abundance of applications,” says a former lead recruiter. “Instead of investing time and energy into making sure the [low performer] was developed, it was like, ‘Whatever, we have 150 more applications. Let’s get rid of that person and take one of them.’ ” (In September 2016, the company would repeat its one-day hiring stunt, this time announcing it would hire 5,000 employees at once.)

As Moran tells me, “There’s no way to force mediocre or low-performing teams to do a great job day in and day out. You can get a clipboard and write them up, and yell at them and tell them to clean stuff, and tell them, ‘If it’s not cleaned by tomorrow, I’ll fire you.’ That checklist management mentality [is] not effective.” In June, when Ells and Moran released the Black Book operations protocols for food safety, they stated, “We’re counting on our empowered teams of top performers to learn all of the high standards that we have for food safety.” If any “symptoms” are discovered, Ells and Moran wrote, “your diagnosis can only be a lack of top performers.”

From Moran’s perspective, Chipotle’s restaurant culture is a thriving meritocracy. Crew members, he and his executive team point out, receive twice-annual merit pay increases, and on average get promoted to kitchen manager within 10 months—a position that comes with a 20% raise—and from there to service manager in another year. In the process, they learn invaluable people, service, and management skills. “We have substantial rewards that we give to our people,” says Hartung. “Some of the national discussion about just increasing the starting wage, it only talks about that bottom rung, like what’s the lowest-paid person willing to earn who works in your company. We think the narrative ought to be more about investing in that person, developing that person.”

The “national discussion” Hartung is referring to is the so-called Fight for $15, raising the federal minimum wage to $15 an hour. Chipotle is sensitive to the impact a 66% increase to its minimum wage of $9 per hour (which is higher than the $7.25 federal standard) could have on its business. Without prompting, Moran defends his compensation. (It would take a starting Chipotle crew member more than 1,500 years to earn his 2014 pay package.) “The only reason I deserve, or anyone [at Chipotle] can deserve, to make more than a GM,” Moran says, “is if they have the effect of empowering or helping loads of GMs get better. That’s the only way.”

Some company observers believe that if Chipotle led the Fight for $15—effectively extending Food With Integrity to the people who serve it—it could help the company reduce turnover, improve training and food safety, better its relationship with its low-level employees, and change the narrative around the company in the wake of this crisis.

Hartung disagrees that it would reduce turnover. “The idea that $15 will solve things, I think it solves it temporarily,” he says.

Not long ago, I spoke with a current crew-level employee who has been with the company for almost two years. He works around 40 hours a week, believes in the Food With Integrity mission, and can handle the line and grills during the lunch rush. “It’s overwhelming, very stressful. The line never dies, sometimes for three hours,” he says. And yet, “The most raise I ever got was 10 cents, up from $9 per hour.”

He still loves what Chipotle represents and the skills it’s taught him—”I never thought I’d be cutting onions and peppers and cooking chicken and able to use a knife,” he says—but he wants a livable wage and has joined the Fight for $15 movement. Even if that isn’t successful, though, he won’t leave Chipotle. “I’ve gotten so far and worked so hard for the company that I’m almost there to becoming a manager,” he says with pride. If he attains this goal, though, he expects his salary to be bumped up just $1.50 per hour. “I wish Chipotle realized that with what we do, selling all this Food With Integrity and their vision that we promote to everyone, we should be getting paid more,” he says. “Why do we earn almost the same as McDonald’s workers when the care we put in is 20 times what they do?”

Chapter 9: The Reckoning

New pressures, lessons learned, and what happens now.

On September 6, Chipotle’s leadership team learned that investor William Ackman had amassed a 9.9% stake in the company through his hedge fund, Pershing Square. In an SEC filing disclosing the position, Pershing called Chipotle “undervalued,” with a “strong brand, differentiated offering, enormous growth opportunity, and visionary leadership.” It also stated its intention to “engage in discussions with [Chipotle’s] management and board of directors” about everything from the composition of the board to the company’s cost structure and strategic plans. Chipotle’s share price jumped nearly 6% on the news.

Ackman is one of Wall Street’s most high-profile activist investors. Known for his controversial bets and caustic approach, he’s not like “those individuals” in Chipotle’s annual shareholder meeting, as Moran described them, who “read proposals and air a protest or two.” In the past, Ackman has taken substantial positions in fast-food chains, including McDonald’s and Wendy’s, and then agitated for them to adopt major transformations such as divesting assets, embracing franchising, and replacing management. (Ackman declined to comment.)