Making your own mask? These are the 5 most important things to consider

The recent Centers for Disease Control and Prevention recommendation to use cloth face coverings to help slow the spread of COVID-19 has generated numerous how-to articles and videos. As academics who focus on personal protective equipment (PPE) research and development, we are concerned about the lack of information on two critical features of home mask design: fit and fabric selection.

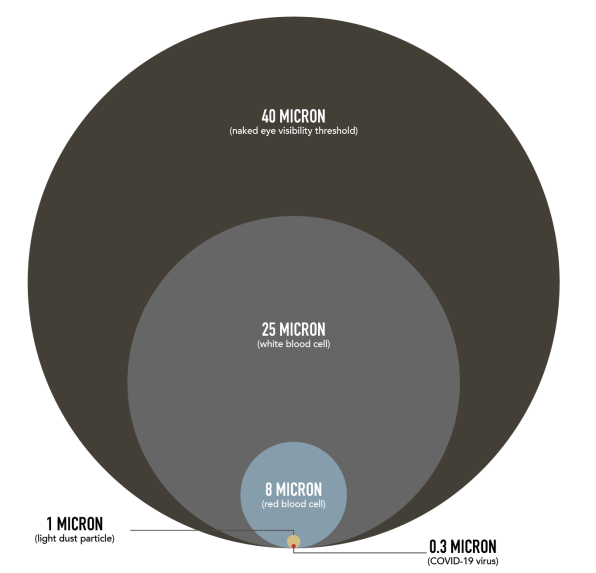

The reality of particle size

Virus particles are tiny, ranging from 0.1 to 0.3 micron. A 40-micron-size particle is visible with the naked eye—anything smaller, you need specialized equipment to see it.

[Image: Susan Sokolowski]

Protective masks such as the N95 are designed to prevent virus particles from flowing in and out of the mask. Due to current shortages, N95 masks should be reserved for COVID-19 healthcare workers only.

Better than nothing

Homemade masks cannot block or filter the SARS-CoV-2 virus, because it can easily flow through every common material people have at home. However, a homemade mask is still better than none at all. If made correctly, a homemade mask can reduce the transmission of the virus from the wearer to others by impeding large droplets and spray produced by a cough or sneeze. It can also reduce the transmission of the virus from others to the wearer.

Fit

Masks should completely cover the nose and mouth. When measuring for a mask pattern, make sure it extends from the top of the nose—as close as possible to the eyes without obstructing sight—to under the chin. Masks should cover the face side-to-side, well past the opening of the mouth.

When developing prototypes, check around all edges of the mask for gaps. If you see any, close them up by pinching the fabric together, and stitch or tape or staple edges together to create a pleat or dart. A thin metal wire or paper clip placed along the top edge of the mask can stabilize and shape it along the bridge of the nose and cheekbone for a closer fit.

Masks should stay securely in position and fit comfortably with ties or elastic ear loops. If the mask is too tight or loose, the wearer may continuously adjust the mask, forgetting the admonition “Don’t touch your face!”

The ties and loops should also be the mechanism for taking off the mask, as the front of the mask might be contaminated.

Fabric selection

People have varying access to different fabrics at home. Masks should incorporate fabrics that:

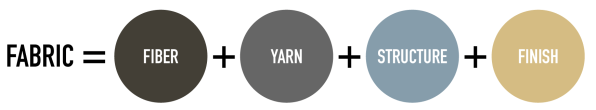

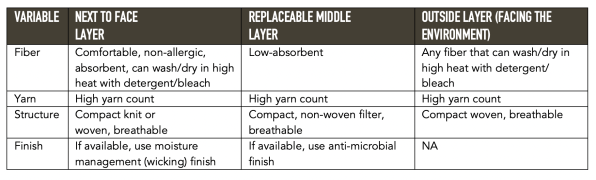

Fabric is comprised of four variables that must be considered for mask making: fiber, yarn, structure, and finish. Change a variable and the mask performance changes.

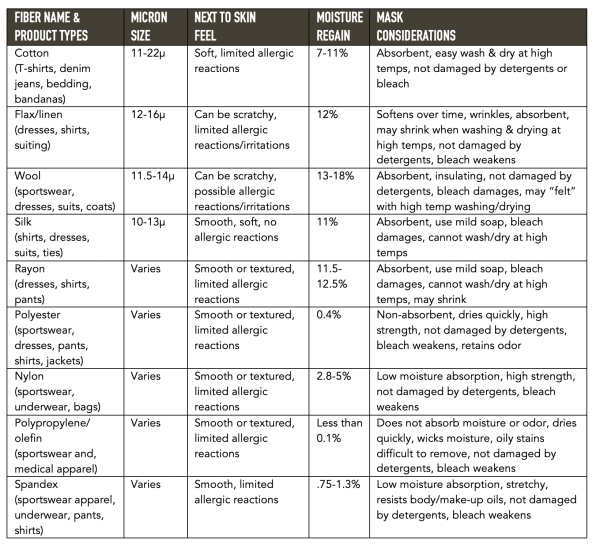

Fibers are the smallest component of a fabric. They cannot be identified by sight or touch. Look for a fiber content label on the products or fabrics you might use for your mask. Alternately, a “burn test” can be used as a crude method to determine if a fabric is a natural fiber, human-made fiber, or a blend of natural and manmade fibers. If you choose this method, be careful.

There are three important fiber characteristics to consider for mask making. The first is micron size—the diameter of a fiber. The SARS-CoV-2 virus particle is 0.1 to 0.3 micron, so small-sized fibers allow for more compact fabric structures to reduce transmission. The second is how the fiber feels next to skin—this will indicate how comfortable a mask may feel next to your face. The third is moisture regain—how well the fiber absorbs moisture. A higher number means more absorbency; low regain gives a sense of how well the fiber might repel moisture.

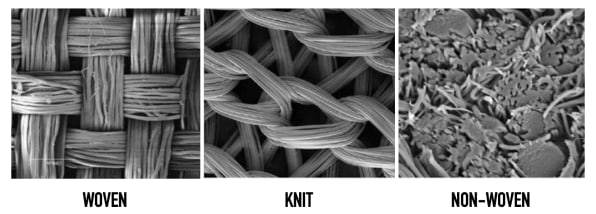

Fibers are twisted together to form yarns. Yarns vary in size, affecting fabric thickness and breathability. “Yarn count” is the number of yarns in a 1-inch square of woven fabric. A high yarn count fabric indicates a dense fabric with droplet-blocking potential. Yarns with different properties can be blended to combine characteristics.

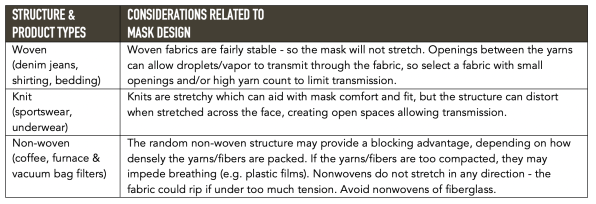

Yarns are then structured into the physical fabric.

Performance finishes, such as water repellency and antimicrobials, are not visible but could be helpful. Detect water repellency or moisture wicking by using an eyedropper to place a drop of water on a fabric to see how it moves across the fabric. Aesthetic finishes such as graphics and batik are not so useful.

Put it all together

There are many fabric variables to reckon with for a homemade mask. Consider building a three-layer system.

This three-layer system includes a space between the inner and outer layers for a removable middle layer. A replaceable “filter” is inserted in that space. If one fabric layer is too thin, add additional layers for protection.

Homemade masks will not filter the SARS-CoV-2; however, masks may prevent droplets and spray from transmitting between individuals. When wearing a mask, remember to continue social distancing, wash hands frequently, and wipe down surfaces and packages.

Susan L. Sokolowski is director and associate professor of Sports Product Design at the University of Oregon, and Karen L. LaBat is professor emerita of design at the University of Minnesota. This article was republished from The Conversation under a Creative Commons license. Read the original article.

(6)