This school’s science project is 3D-printing prosthetic hands for people in need

A few years ago, the then-principal of West Leyden High School outside Chicago, Will Wagner, had a chance encounter on a plane that would change his school’s curriculum. It started when the man sitting next to him pulled a prosthetic hand out of his bag.

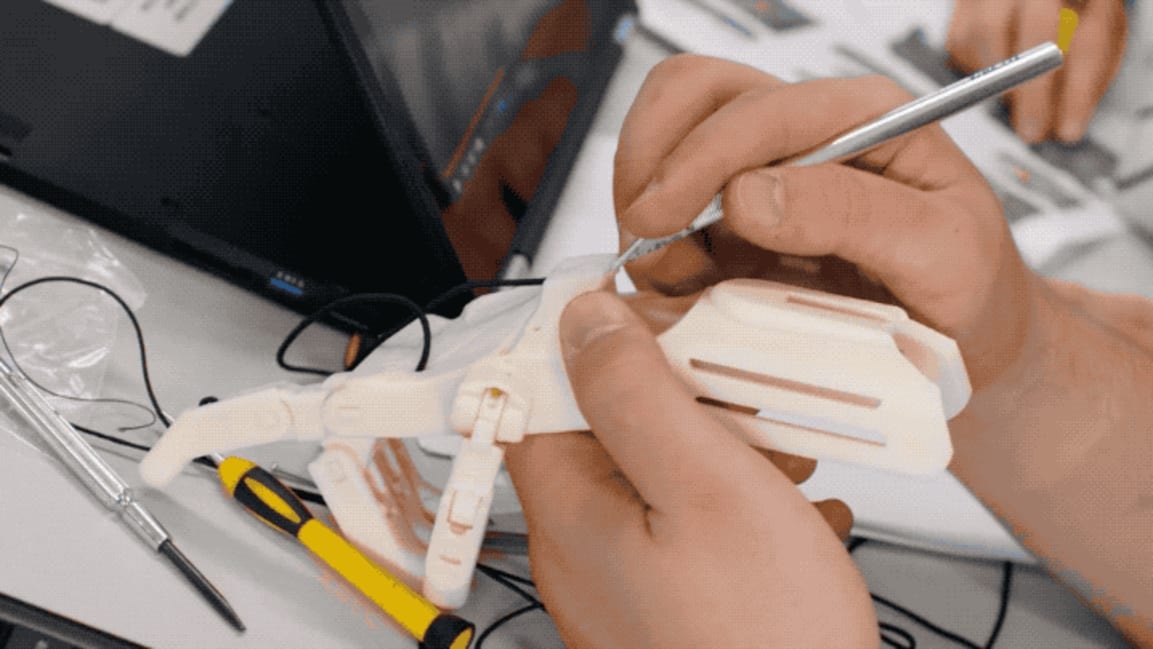

After they started talking, it turned out the man was from a neighboring town and the prosthetic hand was from e-NABLE, a project that uses a distributed network of designers to create and print custom 3D-printed prosthetic hands to people who can’t afford them. The conversation led to Wagner having the school join the program. Since 2013, Leyden students have made about 75 prosthetic hands for kids in the U.S. and in countries like Syria and India. Prosthetic limbs usually cost anywhere from $3,000 to tens of thousands of dollars, while those provided through e-NABLE are free (people in need can post a request on the e-NABLE site and then interested makers can decide to work on their project).

“Anytime you can add authenticity to what you do in the classroom, you’re going to win,” says Frank Holthouse, who taught engineering at Leyden and was at the original meeting that presented e-NABLE to teachers around seven years ago (he’s now the school district’s director of careers and community 0utreach). “The days of worksheets are over, the days of turning things in just to your teacher . . . are over. You have to engage a third party in some way . . . to make it real for the kids.”

Using engineering software and 3D printers to create prosthetics made it very real for students—especially when those participating in the project got to meet the children they were helping. Video-chatting with a boy in Syria who’d lost his hand due to war-related violence, Leyden students could see him testing out the new 3D-printed version, which they’d made in class the previous week.

Today, project e-NABLE is growing—which means, in part, that it’s harder for Leyden students to connect with recipients. “When I started, I would GChat the founder and say ‘Hey, I’m looking for some kids’ and would get the contact info,” says Holthouse. Now that the project has become better known, the process has gotten more formal. Potential volunteers have to submit a “test hand” to prove that their quality of work is up to e-NABLE’s standards before they can officially begin creating prosthetics for the project.

Still, Leyden students continue to participate. Having developed an interest in the work through Holthouse’s initial classes, some students went on to form a club to keep working on the project outside of the classroom. Last year, a freshman in engineering teacher Brian Burcham’s class at West Leyden created a prosthetic hand for his capstone project. “I have this student again, and it’s something we’ll probably do again,” says Burcham.

In high school education, says Holthouse, commitment to certain projects ebb and flow, and student enthusiasm for using 3D printers to create prosthetic hands has recently “sparked back up.” As the school year starts, the engineering club, which meets after school, is looking to invest time in this project. “Whether it’s through e-NABLE or any other sort of outreach, we’re looking at certainly utilizing the 3D printers to serve the community,” says Burcham. Thanks to some grants, Leyden High School has several 3D printers, on both its East and West campuses.

“We’re setting this up to continue this project indefinitely,” says Burcham. “As long as there’s a need.”

(11)