This Startup Is Making Stronger, Stretchier, Softer Silk–And It’s All Done In A Lab

Bolt Threads just raised $40 million to put silkworms and spiders out of a job.

Your next shirt might be partly grown from yeast and sugar in the lab.

Bolt Threads, a Bay Area startup that announced $40 million in new funding today, has figured out how to make engineered silk fibers at scale, using a process that can “tune” silk proteins to make them stronger, stretchier, or softer than the natural version made by silkworms or spiders.

“With any natural fiber, you’re kind of stuck with what nature gives you,” says Dan Widmaier, co-founder and CEO of Bolt Threads. “The silkworm makes one silk. You collect each season from the farm, you grade it, and whatever the best grade is, that’s what you’ve got and those are the properties you have.”

For decades, researchers have been fascinated by the properties of silk as a material. Spider silk, for example, is famously stronger than steel by weight. But until recently, it’s been difficult to create an artificial version.

Now, like Bolt Threads, a number of biotech companies, such as Kraig Biocraft Labs and the Japanese company Spiber, are close to or starting to produce commercial products. They want to use the material to create everything from bulletproof vests to surgical sutures.

“Advances in DNA sequencing since the 1990s opened the door to tuned properties, but there were many pieces of the puzzle that had to be solved in order to do it consistently, at scale, and at a cost that made it commercially viable,” says Widmaier.

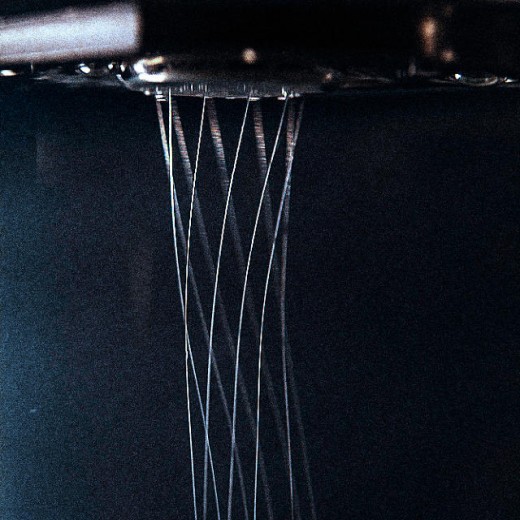

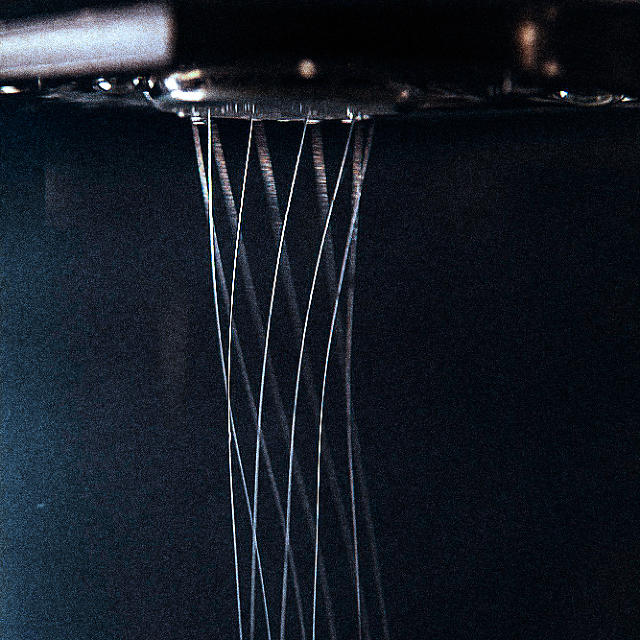

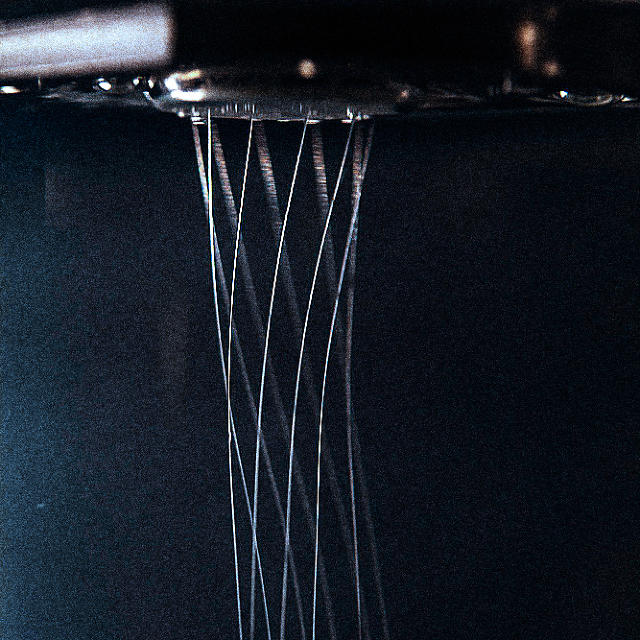

The startup uses yeast engineered to make silk protein, and grows it in fermenters similar to what you’d find in a brewery making beer. After purifying the protein away from the yeast, they spin it using a process similar to making rayon or nylon. The result is engineered silk.

It can look and feel exactly like fabric made using silkworms—but it can also be better, both because it can avoid the unpredictability of the natural production process, and because the proteins can be engineered to have whatever qualities an apparel company wants.

“Silk today is a fiber that’s the ultimate luxury fiber, it’s soft, it’s strong, it drapes really well, it’s got a great luster to it, and that’s great,” says Widmaier. “But it’s also fragile and doesn’t care for well, it yellows over time, and there’s all these things that are wrong with it as well. That’s the give and take of natural fibers.”

The company’s new line of performance fabrics may also eventually start to replace petroleum-based materials like nylon. “There’s room to make both higher-performing and more sustainable fibers,” he says. “The beauty of making a protein-based fiber is you get sustainability in the form of it’s grown from nature and can be recycled by nature.”

[Cover Photo: Humannet via Shutterstock]

Fast Company , Read Full Story

(119)