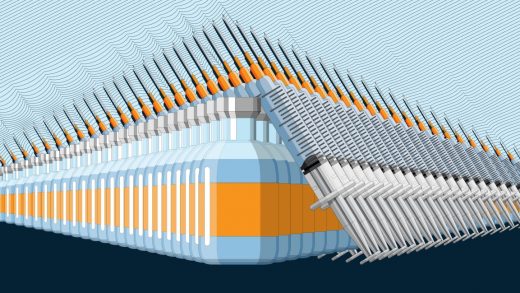

UNICEF is stockpiling half a billion syringes to get ready for a COVID-19 vaccine

Inside a warehouse in Copenhagen and another in Dubai, UNICEF is racing to stockpile hundreds of millions of syringes. It’s the other half of the long path to an effective COVID-19 vaccine: As some pharmaceutical companies reach the final stages of vaccine trials, the UN agency is working on the logistical challenge of how to quickly deliver those vaccines around the world as soon as they’re approved.

The agency, which provides humanitarian and developmental aid to children, normally works on childhood immunizations in low-income countries. But since the coronavirus crisis means that virtually the whole world will need a vaccine, UNICEF is now working on broader vaccine distribution, in what executive director Henrietta Fore calls “one of the largest mass undertakings in human history.”

A program called the Covax Facility has arranged deals with dozens of countries so that when a vaccine is ready, it can be distributed equitably—a reaction to the problem of “vaccine nationalism,” where countries like the U.S. are reserving doses only for their own citizens. The program will begin with doses for 3% of each country’s population (healthcare workers and others who are most vulnerable will go to the front of the line), later increasing to 20% of the population when more doses are available. While it’s hard to predict what will happen in vaccine trials, it’s possible that one or more vaccines could be ready by the end of the year. By that point, UNICEF wants to have 520 million syringes in stock and ready to go. By 2021, 1 billion syringes will be in place.

In July, it started placing orders with syringe suppliers well in advance, realizing that demand would increase later in the year, and that it would also need time to get supplies to each country. “Vaccines are always shipped by air because of cold storage requirements and the need for temperature control,” Matthews says. “So the shipment goes relatively quickly, whereas the shipment of the associate syringes and safety boxes takes normally between two to four months to be shipped by sea because they’re far bulkier.” Each delivery will include special syringes that can only be used once, to prevent any spread of blood-borne disease, and thick boxes that can safety store the used syringes. Other organizations are working on other parts of the logistics puzzle, like making sure there is enough glass available to make all the vials necessary to transport the vaccine.

UNICEF is also working on other key parts of the logistics puzzle, such as plans to charter flights to deliver vaccines. Most vaccines need to be kept at cold temperatures or they become unusable; in areas where electricity is unreliable or doesn’t exist, keeping the vaccines viable will be another major challenge. By the end of 2021, the agency—which is currently mapping out where refrigerators exist—plans to install 65,000 solar fridges in developing countries.

All of the efforts are an extension of its ongoing work. Next year, for example, in addition to the billion syringes it will have ready for COVID-19 vaccines, it will also order another 620 million syringes for other vaccines such as measles. “We’re well experienced in doing this procurement,” says Matthews. “But, of course, the magnitude of what we’re dealing with in terms of the rollout of the anticipated COVID vaccine is a significant scale-up, over the next couple of years, in terms of the sheer volumes that we’re talking about.”

(15)