Universal Hydrogen’s Paul Eremenko is on a mission for zero-carbon flight

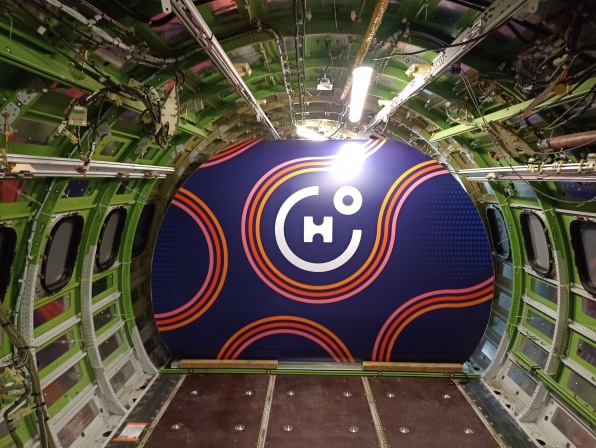

Two 600-gallon fuel tanks, awash in groovy retro-modern swirls of purple, pink, and orange breach a sea of gray machinery. Nearby, a powertrain testbed spreads across a workstation in a tangle of wires entwining a blue metal frame. At a glance, the industrial gallery gracing this small Los Angeles area airport hangar doesn’t register as visionary. But if Paul Eremenko has his way, this unassuming engineering test kitchen will serve up a revolution in aviation and a strike against global warming.

While it involves hydrogen-powered flight, that’s not the novelty here. The first experimental hydrogen-powered aircraft flew in 1988, with startups to multinationals now addressing the challenge for commercial fleets. What is novel is rethinking hydrogen delivery for aviation. Eremenko and Universal Hydrogen (UH)—the three-year-old startup that the clean aviation pioneer and CEO cofounded with general counsel Jon Gordon—are tackling the missing logistics to make carbon-free flight economically viable.

The real hurdle will be convincing the industry to get on board: getting the system FAA-certified for commercial service by 2025; then converting enough smaller fleets in time to prove this approach to Boeing and Airbus before they lock down designs for their next-generation jetliners. “Everything we do is with that goal in mind,” he says.

There’s just one catch: UH has to do this in five years.

But first comes the maiden test flight on March 2, when a retrofitted Dash-8 airplane draped in the same vibrant colors plus the company’s polar bear mascot takes a 20-minute spin from Grant County International Airport in Moses Lake, Washington.

Dash 8 and ATR-72 models, 40-60-seaters that fly routes up to 600 miles, comprise the lion’s share of the regional turboprop market with just over 2,400 combined planes. UH has airline orders to retrofit around 10% of that market and expects to tackle half of it. Decarbonizing most regional air travel, which accounts for seven percent of aviation emissions, could influence narrow-body aircraft—the single-aisle carriers that typically seat 150-200 passengers and fly transcontinental and occasionally transatlantic routes.

Boeing and Airbus are rethinking these models for better efficiency, improved passenger experience, and cleaner emissions for a mid-2030s rollout. Eremenko (himself a former Airbus CTO) expects them to finalize those designs around 2028 and wants UH to be ready when they do. The sheer number of narrow-bodies and their flights produce 51% of all aviation emissions. “If we do the single-aisles in the 2030s and the big wide-bodies in the 2040s, by 2050, this industry could get to zero emissions,” he says.

Aviation is one of the hardest industries to decarbonize, because of weight, regulatory, and safety hurdles. But it’s not trying hard enough, Eremenko insists. Airlines are slowly adopting sustainable aviation fuel (SAF), pricier bio and synthetic fuels with lower carbon footprints than conventional propellants. But that falls far short of hydrogen engines, which take 3.5 times less energy to produce and emit only water as “exhaust.”

“The default reaction in the aviation sector is, `’It’s too hard to change the airplane engine. So we’re stuck with kerosene, but let’s try to make it slightly cleaner kerosene,’” he says. “Hydrogen is always the best fuel, but there’s no hydrogen logistics network to get it to the airport and into the airplane, and it’s nobody’s job to build one. So, we made it ours.”

Eremenko likens the UH solution to a Nespresso coffee maker and pods. “They buy coffee and ship it to their customers in pods designed to fit their coffee maker. We buy hydrogen and put it in this convenient capsule that can be transported to the customer by truck and slotted into their retrofitted engines,” he says.

Eventually UH plans to outsource its engine manufacturing and focus solely on delivering hydrogen for aviation and, other mobility industries. “We don’t want to be in the coffee machine business. We want to be in the capsule as a service business. But we have to build the first coffee maker; that’s our conversion kit for regional airplanes, and what’s going to fly [March 2].”

It’s a bold vision for the 100-person company, albeit one backed with nearly $100 million from such powerhouses as Airbus Ventures, General Electric, American Airlines, JetBlue, and Toyota. (UH needs another $200 million or so to get hydrogen regional airplanes into commercial passenger service.) But Eremenko brings a formidable background: The Ukrainian-born 43-year-old boasts degrees from MIT, CalTech, and Georgetown University Law School, executive positions at DARPA, Google, Airbus, and United Technologies, and a pilot’s license before he could drive.

Not to mention, there is a sense of urgency with worsening climate change. Eremenko has grown increasingly frustrated with aviation’s lax response to Paris Agreement goals. They involve reducing carbon dioxide emissions to net-zero by 2050 in an effort to keep average global temperatures from rising more than 1.5 °C (2.7 °F)—a target some scientists already doubt is possible. Aviation contributes roughly 2.5% of total global emissions, exceeding the output of some countries, and only threatens to grow. Air transport is expected to increase by an average of 4.3% per year over the next 20 years, with 10,000 more commercial airliners by 2032 and 200,000 daily flights by the mid-2030s, to triple industry emissions by 2050.

“[Aviation] companies make incremental improvements just enough to stay apace with the competition. Nobody wants to stick their neck out and be like, `‘I’m gonna do something fundamentally different,’” because it demands too much money, risk, and rejiggering factories, design tools, and workflows, says Eremenko. “When I was at Airbus, one of my big frustrations was that we as an industry would set fake targets. `We can’t meet Paris Agreement goals, so we’ll set new goals that are less stringent that we can actually meet.’ And I was like, “‘Eh, this doesn’t really work for me.’”

Net-zero vs true zero

The problem is that current carbon reduction and offsetting methods—like using SAFs or funding tree planting—won’t counter aviation’s anticipated growth, a view Eremenko laid out in an opinion piece in Fast Company last year.

SAFs capture some CO2 in production, which offset some of the environmental impacts of burning a hydrocarbon (kerosene) at 35,000 feet. However, their capture processes are inefficient, more expensive, and don’t always remove the amount they put in. The algae used for many jet biofuels offsets a small portion of CO2 but consumes huge areas of biomass, creating another negative environmental impact. Synthetic fuels attach carbon atoms from CO2 sucked from the air to hydrogen to fabricate hydrocarbon molecules (synthetic kerosene), only to reintroduce that carbon into the atmosphere when they’re burned.

“If the amount of carbon in the air is producing these climate change effects already, we need to remove it,” says Eremenko. “If you want to truly decarbonize the sector and do `true zero’ instead of `net zero,’ you have to use green hydrogen.”

Hydrogen vendors make green hydrogen by running electricity generated by wind, solar, or hydropower through water to split it into hydrogen and oxygen. (Compared to extracting it from carbon-containing molecules, like methane.) On regional plane engines, hydrogen feeds through a fuel cell where it reacts with oxygen from outside air to produce electricity, propelling the aircraft and releasing water. On narrow-bodies and larger aircraft, hydrogen burns in the jet engine with the same efficiency as a conventional one, while still emitting only water.

But hydrogen presents unique logistical hurdles. While it packs significantly more energy per unit of weight than kerosene, hydrogen requires four times more volume for the same energy content. That means fueling takes four times longer, which would greatly lengthen the typical 30-minute turnaround time between commercial flights. There’s also a high leakage rate. A combination of hydrogen’s tiny size and cooling requirements results in losses that can range from five to fifteen percent with each transfer from one vessel to another. The UH modular approach addresses these challenges. The fuel capsule swap can occur in a few minutes and keep losses down by eliminating the numerous transfer operations.

Harnessing public opinion

For a company under such severe deadlines with its first test flight looming, the atmosphere at its headquarters is focused but remarkably chill. Wild doves flit around the rafters of its airy converted hangar at the Hawthorne Municipal Airport, down the runway from SpaceX. Dogs are so encouraged at work that they even merit a profile section on the UH website. The prototyping shops occupy another two hangars here and one at the Toulouse–Blagnac Airport in France, with a manufacturing center earmarked for Albuquerque International Sunport in 2025.

The colorful graphics on the UH capsules and test planes are a reflection of this vibe, a hip eco-friendly image that UH wants to present directly to consumers, despite being a B-to-B company. The idea is to build brand loyalty and environmental cred with travelers through social media and possibly a UH hydrogen frequent flyer program to help pressure the airlines.

But can such a grassroots campaign sway consumer behavior enough to counter the Big Oil lobbies for synthetic kerosene?

Eremenko sighs. “We’re getting a run for our money.”

Lessons from DARPA

Climate change warrior wasn’t initially on Eremenko’s career radar. When he moved to the U.S. at 11, he was more into space and briefly considered following in the footsteps of his father, a mathematician at Purdue University. That shifted when he sought flying lessons to escape the boredom of his Indiana suburb, earning his pilot’s license at 17. That experience prompted him to study aeronautics at MIT and CalTech, where he earned a master’s in 2002. After a circuitous route from an unmanned aircraft startup to management consultancy to law school, he found his calling overseeing innovation initiatives at the DARPA, Google, Airbus, and United Technologies. Eremenko met Jon Gordon at Airbus and they continued working together at United Technologies, where Gordon was deputy general counsel.

By 2019, climate change had taken center stage in transportation, and Eremenko’s career journey had given him the skills and knowledge to piece together the roadmap to more sustainable aviation.

“I wasn’t born dreaming of hydrogen,” he says with a laugh. “It was a means to an end.”

He and Gordon left United Technologies that year to chart a course for UH, which they founded in March 2020—just days before the pandemic shut down New York, where they’d been living at the time—and publicly announced the company the following September.

Of all Eremenko’s positions, helming the Tactical Technology Office at DARPA, where his work included modular satellites (groups of satellites that work together), would have the most profound impact on his current leadership style and technical strategy. “DARPA was a truly magical place and the watershed career event for me,” he says. “It was my first real deep dive into modular architectures and showed the value of time constraints as a way to catalyze innovation.”

Modularity enables engineers to build complex systems through isolated parts, so one change doesn’t create a cascade of them throughout the system. He would carry that thinking with him to Google, where he worked on a modular smartphone, and Airbus, where he developed concept airplane cabins that could be reconfigured per flight needs and length—like a gambling module for Las Vegas hauls. Modular design informed UH’s hydrogen delivery system, while the short window to prove the technology before Airbus and Boeing launch their next new airliner program has imposed the constraints leading to its innovative solution.

“Time pressure typically focuses engineers, so you get the best out of them,” he adds. “This idea of setting a big ambitious goal but then having a very pragmatic sequence of near-term milestones that contribute to that goal is a very DARPA way of thinking.”

If Eremenko is successful and UH facilitates widespread adoption of hydrogen-fueled planes, it will be a significant step for aviation, but not solely keep temperatures from rising. That still demands a concerted global effort to mitigate greenhouse gases across manufacturing and countries. But one step at a time. Eremenko is heartened by small recent attitudinal shifts in his industry. “People are saying, `Yeah, we will commit to net zero in 2050.’ I’d like to think that we are part of driving that change.”

(16)