Watch: Boeing On How They Developed the arena’s Lightest subject material

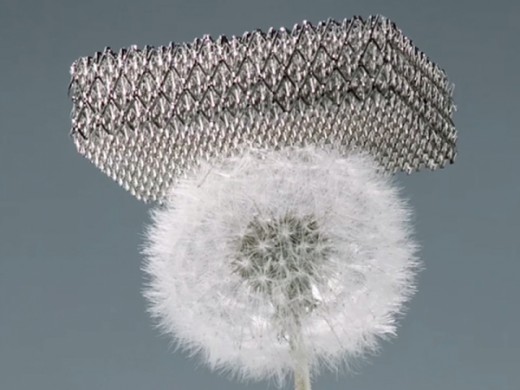

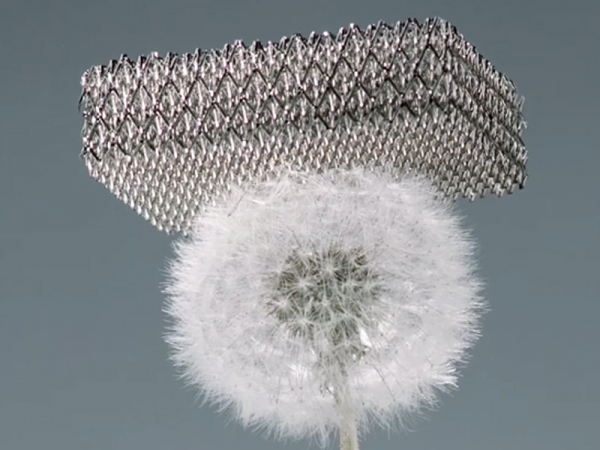

Their “microlattice” metal is one hundred instances lighter than styrofoam however sturdy sufficient to be used as structural elements in airplanes.

October 12, 2015

For years, Boeing has been developing an especially lightweight material which may be used for airplane parts. regardless of being constructed from metallic and being nearly as strong as titanium, the fabric is one hundred times lighter than styrofoam.

This week, they launched a video explaining how the fabric is made:

the secret to the weightlessness is in the structure: the material is made up of a lattice of interconnected hollow tubes which are 1,000 times thinner than a human hair. The video likens the structure of the steel to bone structure—hole within the heart however no longer simply beaten, and light-weight at the similar time. the complete structure is 99.99% air.

Naturally, Boeing is taking a look into purposes of the fabric in structural elements for aerospace. “after I get on a aircraft and i am leaning against the sidewall panel and placing my baggage within the stow bin or i’m walking along the floor panels, i believe the microlattice could be utilized in any such eventualities,” says Sophia Yang, research scientist for HRL, the analysis institute that does R&D for Boeing. changing heavier metallic parts with microlattice material would shop quite a lot of fuel, and its springy subject material might be useful for absorbing sound and heat.

additionally it is value noting that HRL is jointly owned with the aid of general Motors, so it’s possible scientists are additionally considering methods to use microlattice for automotive parts. and because its simple to manipulated and produced speedy, it’s excellent for fast manufacturing.

[by means of Core77]

(88)