Why We still do not have low cost, Customizable 3-d Printed sneakers For All

lately, three-D-printed sneakers are luxurious experiments. here is what it will take to make shoes people actually want (and may have the funds for) to put on.

could 5, 2015

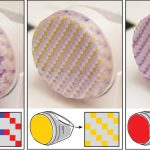

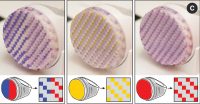

The premise used to be promising. United Nude, a sneakers firm recognized for its experimental designs, enlisted 5 industry heavyweights to create 3-d-printed high heels that pushed the boundaries of the expertise. partner 3D systems would manufacture as much as 50 pairs of each type, making them the de facto first commercial runs of 3-D-printed shoes.

And the consequences, crafted via the likes of Zaha Hadid, Ross Lovegrove, and Michael young? The shoes equivalent of guitar solos: all technical process with little sensible perform. Plus, at $6,000 a pair, priced some distance from three-D printing’s promise of low-cost design for all.

For fairness’s sake, United Nude is advertising the nylon-and-rubber pumps as collectible objets, now not on a regular basis kicks. Plus they did debut in Milan, right through the furniture honest, so spectacle was implied.

[

[but if a producer as clued-in as United Nude can’t pull off developing reasonably priced 3-d-printed shoes, who can? and the way?

First step is to keep what isn’t damaged. “It’s silly to three-D print a complete shoe,” says Duann Scott of Spark, Autodesk’s open-supply 3-D-printing platform. “Mass-producing a shoe in the conventional way prices a couple of greenbacks maybe, whereas three-D printing one prices a whole bunch because of time and materials.” better is to leverage the expertise’s strength—its ability to customise—and print most effective the shoe parts that would take advantage of it, corresponding to insoles or cleats.

It’s a lesson SOLS CEO Keegan Schouwenburg realized when her firm, which specializes in customized 3D-printed orthotics, tried to extend into shoe soles. “They have been too expensive to make, and the materials were not there relating to durability and elasticity,” she says of the latter. “As soon as we bought the soles to the check segment, people asked the place the gel, the leather-based, and the foam had been—these supplies associated with comfort.”

Bendable, versatile options like NinjaFlex do exist to be used in 3-d printers. however the materials’ excessive costs—the result of the best way they’re made and offered—prevent mass-market use.

every 3D-printer producer creates the materials used in its machines. just like the pharmaceutical business, each and every then patents what it makes, locking down exclusivity on its supplies (and know-how) for up to 20 years. That inflates costs.

Take ABS plastic, popular in rapid prototyping. utilized in pellet form for injection molding, the fabric averages $5 per kilogram. then again, when in the filament reels required for three-D printing, the fabric levels from $30 per kilo (widely wide-spread) to $ninety for variations within the “chipped” cartridges required for some machines.

yet indicators of change are on the horizon. 3-d printing began in the early Eighties, so a number of the core patents for its applied sciences, including ones used for Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), have expired. while a lot of ones around machine operations and materials nonetheless exist, lower-priced options are flooding the market. “now we have already viewed this with the explosion of FDM printers,” Spark’s Scott says, noting these desktop machines, popular with the maker set, have dropped in worth previously 5 years from $20,000 each and every to not up to $1,000.

With extra inexpensive expertise will come “a Cambrian explosion of material innovation,” Scott provides. To that end Spark recently presented Ember, a stereolithography (SLA) 3D printer, to finish the platform’s open-source process, as well as spur material and technological innovation.

however the remaining step to achieve that mass-market intention? tool aimed at the type industry for developing and printing 3-D wares. architecture, product design, and the movie business use the lion’s share of 3-D packages, while clothing designers have been recognized, out of form and wish, to hack previous milling instrument. (stated United Nude founder Rem D. Koolhaas about why he didn’t embody any type designers in his exhibit: “type designers normally don’t work in three-D in an advanced method. Even Iris van Herpen [United Nude’s typical collaborator] wants architects to get all her 3D work executed.”)

packages being developed with the aid of Francis Bitonti, who customizes structure and CGI instrument to provide his personal three-D-printed fashions, could lend a hand footwear designers understand their concepts themselves.

but it could also be so simple as pairing a 3-D design knowledgeable with a way dressmaker, echoing the way garments and footwear had been designed for hundreds of years. “If we recall to mind the 3-D dressmaker as a craftsperson in the same method we call to mind a conventional sample maker, the collaboration course of from a sketch, to iteration through experimentation across the important points, will not be so completely different,” Scott says.

So given time and some strategic considering, mass-marketed 3-D-printed sneakers might be a truth just yet. “i feel it will take three to five years,” SOLS’s Schouwenburg says. “however even then, it is going to be components, a mixture of supplies. something like Nike’s Flyknit digital weaving or [Adidas’s] Springblade soles.”

[All Photos: via United Nude]

fast company , learn Full Story

.fc-widget

margin: 0 auto;

width: 250px;

padding: 20px 0;

#awards-enter-button

cursor: pointer;

font-measurement: 14px;

textual content-grow to be: uppercase;

font-weight: 700;

font-family: ‘MuseoSans’;

historical past: none;

border: none;

heritage-shade: #91b93e;

coloration: white;

padding: 13px 20px;

#awards-enter-button:hover

history-coloration: #6F8734;

#awards-enter-button a

border-backside: none;

colour: white;

(176)