You Won’t Believe What It Takes To Move A 2-Ton Satellite Across California

You may not have heard of DigitalGlobe, but you’ve definitely seen its work in action.

For over two decades, the company has been capturing high-resolution pictures of the Earth and selling them to organizations you’re familiar with. Much of Google Earth, Google Maps, Apple Maps imagery and surveying systems used by the U.S. government is provided by DigitalGlobe. Its photography has been used for everything from disaster relief to city planning to simply helping your Uber driver figure out where he’s taking you.

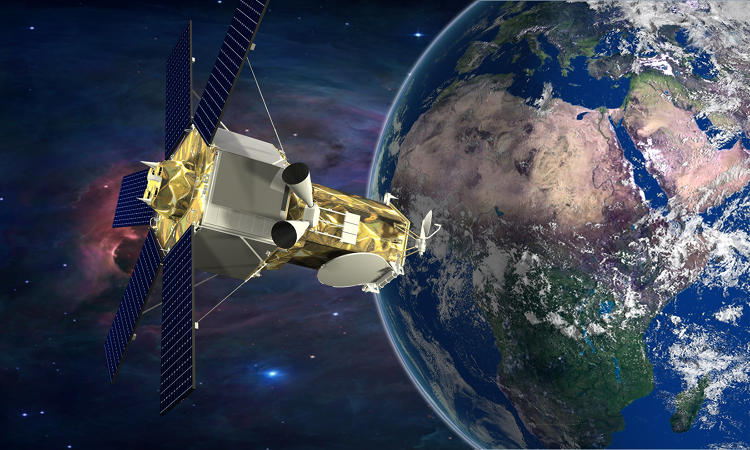

On September 15th, the company is launching a brand-new satellite, the WorldView-4, into orbit. This technology is the third generation of the company’s camera system, one that promises to take pictures in even higher resolution because the lens inside it is even thicker. While there have been some advances in using lighter materials to reduce the weight and size of lenses over the last decades, taking high-resolution photographs still requires having very large mirrors and wide diameter lenses. This particular one is 3.6 feet in diameter and made by the Harris Corporation.

This means that the company is essentially flinging a satellite the size of a truck into orbit, weighing 5,500 lbs., and measuring 15 feet long and 7 feet wide. And while DigitalGlobe isn’t able to share exactly how much this particular satellite costs to build, it’s on par with the Worldview-3, the company’s previous satellite, which is valued at $650 million.

The satellite itself was built by Lockheed Martin Space Systems in Sunnyvale, California. Michael Jordan, the chief systems engineer for Worldview-4, has been working on this particular one since 2010. The camera inside is a scientific marvel. It will be orbiting the Earth at a speed of 17,000 miles an hour, but will be able to capture the sharpest, highest-resolution images available on the market.

“If your hand shakes while you’re taking a picture, it gets blurry,” Jordan says. “Our satellite isn’t stopping. Our job has been to tightly control and stabilize the satellite, so while it is moving at that velocity we can take a picture without it coming out blurry at all.”

Over the last few weeks, he’s been working on transferring it to the Vandenberg Air Force Base’s Space Launch Complex near Santa Maria, California, about 245 miles away. “It’s a bit bittersweet for me,” Jordan tells Fast Company. “I was with it since we were designing it on paper and here we are sending it off.”

But sending it off is easier said than done. Jordan talks me through the laborious process of transferring the satellite from the lab in which it’s built to the launch site and then into outer space.

Beware Of Germs

Satellites such as this one are built in pristine conditions, in rooms where every aspect of the environment is carefully controlled. As Jordan and his team were building it, they wore clean-room suits, special booties, and hair bonnets. “We’re building something that is designed to last a long time—at least 7 years—in outer space, without any human intervention or human interaction,” Jordan says. “No astronauts are going out there to fix it.”

The engineers are extremely careful during the building process because they don’t want any foreign objects, debris, or moisture to enter the satellite and somehow affect its operation in the future. “Anything that’s not controlled, over years of service, can degrade your satellite in unintended ways,” Jordan says.

To transport the satellite to the Vandenberg Base, Lockheed Martin had to create a container that retained all of those pristine conditions, but it also had to ensure that all shocks and vibrations were absorbed to prevent any of the technology from getting dislodged in motion. “We call it the ‘eagle container,'” Jordan says. “It’s a clean room on wheels.”

Not Even A Branch Will Touch It

Given the size of the satellite, this eagle container had to be enormous. It takes up two entire lanes on the California 101 highway. So Jordan and his crew had to work to prepare the route. Lockheed Martin had to work with the California police and transportation authorities to block out the highway during the drive over, which happened in the dead of night, to ensure that it did not hold up too much traffic.

But before taking the ride over, Lockheed Martin wanted to make sure that the route itself was clear and safe, with nothing that might bump the vehicle or get in the way. “When you’re talking about something that takes so long to build and that’s going to be used in space for so many years, the last thing you want is to accidentally run into something,” Jordan explains.

The company designed a special laser radar system to map the route ahead of time in 3D. It can detect things that are as small as a quarter of an inch thin. It was looking out for anything from wires to low hanging branches to overpass height clearances.

The Journey Into Space

Last week, the satellite arrived at the Base and Jordan had to hand it off to the launch experts. DigitalGlobe has worked with United Launch Alliance to take the satellite into its final stage of the journey into space. On September 15, it will go up on the Atlas 5 401 rocket, which is one of the most reliable and quiet rockets available, ensuring that there will be as little shock as possible.

The satellite will be flung 617 km into space. (That’s the distance between San Jose and San Diego.) But the voyage will be very quick. It will go from launch to orbit in under 15 minutes.

But since the task of the satellite is to take the best possible pictures, the engineers have to be very careful about exactly how it orbits the Earth. Photographers describe the perfect moment to take pictures as the “golden hour.” This is when the sun is directly behind the subject, offering the perfect lighting conditions. Jordan explains that a similar logic is used to determine where the satellite should be positioned in orbit.

The satellite will be taking pictures at exactly 10:30 am local time on Earth, wherever it is in the sky. “This means the sun is in the exact right position, such that every time it is flying over the equator at 10:30 am,” he says. “That is the right amount of sunlight we want at the right angle to take a really beautiful picture.”

After seeing the satellite safely to the base and letting the launch experts prepare it for its journey ahead, Jordan went home, a little forlorn. He’s been working on this satellite for six years, watching it grow and evolve every single day. Now he feels a little like an empty nester. “I think this is how I am going to feel when I send my kid to college,” he says. “I’ve also lived with it for so long. When it was finally out of my sight, I was really sad. But on the other hand I’m glad our satellite is graduating. I’m looking forward to seeing it go off into space and achieve these great missions for science and humanity.”

The 2-ton satellite was built in a clean room in Lockheed Martin’s Sunnyvalle, Cal. headquarters.

Engineers are careful not to let particles or moisture enter the satellite.

Click through to see images taken from Digital Globe’s satellites and the new Worldview-4 satellite en route to the air base.

Fast Company , Read Full Story

(95)