As MakerBot Struggles, personal computer Milling Machines Are On the upward thrust

The maker group is embracing inexpensive mini-mills designed to desktop wooden and metallic.

June 9, 2015

MakerBot’s three-D printers will soon be capable of produce objects that seem like bronze, limestone, and wooden, due to a brand new line of plastic-based composite materials shipping later this 12 months. however the launch may be too little, too late: Entrepreneurs and artists occupied with working with metallic and wooden are already embracing laptop milling machines that may handle the true deal.

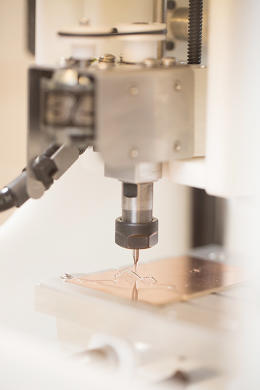

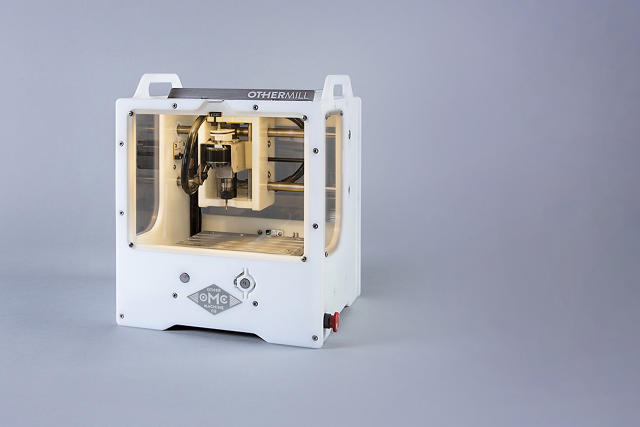

The calculation is understated: purchase a MakerBot Replicator, the prime pc three-D printer, for $2,889, and that you could produce plastic prototypes or the kind of trinkets that you could to find in a contented Meal. buy a small-scale milling laptop just like the Othermill, which retails for $2,199, and that you may make jewellery and mechanical parts out of the whole lot from aluminum to walnut.

“once you can reduce metallic, that you could make things that closing,” says Danielle Applestone, chief executive of different computer Co. “For the primary couple of months that I was working here, I was once afraid of cutting with metal. It was louder, I was worried I used to be going to break the software. however as soon as I jumped in, it speedy become like wax to me.”

“metal is power, it in reality is,” she says. “You don’t return.”

Milling machines, which subtract subject matter—in the most simple phrases, that you would be able to recall to mind them as “good” chisels—are having a moment, as entrepreneurs launch affordable fashions on Kickstarter and crafters uncover their potential, through tool far friendlier than the G-code of outdated. Printers like MakerBot’s Replicator, in distinction, all of sudden seem higher fitted to celebration tips. Undercurrent, a big apple-based totally digital agency just lately got by using Quirky, used to wow shoppers journeying its Soho offices by 3D printing a plastic whistle right through the course of their assembly. It was a neat gimmick, however one emblematic of the challenges going through 3-d printing firms catering to consumer audiences.

while no one disputes that 3D printing or additive manufacturing is growing fast—research analysts at Canalys challenge that the market can be value $16.2 billion via 2018, up from $2.5 billion in 2013—the overwhelming majority of that increase is predicted to return from industrial applications in fields like medicine and aerospace. pc 3D printing, for hobbyists and small-scale fabricators, has so far didn’t reside up to the hype surrounding it, and the latest tribulation at trade poster child MakerBot is working example. Brooklyn-based totally Makerbot announced layoffs, value discounts, and three retailer closings in April. in step with Motherboard, the corporate fired 20% of its 500-member personnel.

“These organizational moves are part of the continued scaling of MakerBot,” David Reis, chief govt of Stratasys, MakerBot’s dad or mum firm, said in a statement. Former employees are less oblique, describing administration as horrific at worst and questionable at easiest in Glassdoor reviews. On Amazon, shoppers were blasting the corporate’s most recent, fifth-generation Replicator as “a whole disaster,” and “not ready for high time.” MakerBot executives declined to be interviewed for this story.

“we don’t predict pc milling machines to affect our trade, because we imagine that both technologies will continue to counterpoint every different,” spokesperson Johan-until Broer informed fast company. “A desktop milling machine can be a great addition to a MakerBot pc three-D Printer and is another software within the maker’s toolbox.”

more and more, although, a pc mill could be a maker’s only laptop. On the decrease finish, there are customizable kits like Inventables’s X-Carve, which requires some assembly however begins at simply $799. For $2,500, there are alternatives just like the Carbide3D, which takes a few swipes at three-D printers in its advertising supplies (“able to make actual 3D components?”). And for around $three,500, there are innovative fashions just like the Pocket NC, a 5-axis computer mill, set to ship next year.

“a big mill is $10,000; you need half a garage. The little laptop mills are pretty good,” says Mark Hatch, CEO of TechShop, a membership-based chain with eight places. For $125 per thirty days, members—a lot of them aspiring entrepreneurs—gain get right of entry to to TechShop’s laser cutters, printers, mills, and lathes.

Hatch estimates that 70-eighty% of the jobs being accomplished on TechShop’s computer 3D printers are prototypes, not completed merchandise. “that you may iterate two or thrice in a single day, and that’s extremely highly effective,” he says. “every so often it’s just right enough. every now and then it’s an inside part so it doesn’t in point of fact subject what it seems like.” but for completed products, or jobs like customized gears, more correct machines that can accommodate wood or metal are in most cases a greater match. common 3-D printer plastics, he says, should not have “the compression potential, the strain.” And for many contributors, contracting out jobs to industry-quality three-D printers, who can accommodate a much broader vary of supplies, is not low-priced. “while you amortize the fee, in many instances you must simply mill that baby out,” he says.

Jony Ive consents. to test their concepts, the Apple body of workers members working in Ive’s well-known design studio don’t use 3-d printers; they use three computer-numerical-control (CNC) milling machines, the desktop fashions’ full-measurement similar. according to the New Yorker, Ive wished the machines “to be as integrated into the studio as noise and dust pollution allowed,” on account of their potential to form the metals and other materials that distinguish Apple merchandise.

i am typing this story on a MacBook Air that Apple machined on a CNC, positioned on top of a simple standing desk that I designed and machined on a CNC. it can be simple for me to imagine having a desktop CNC at dwelling, as a way to make custom kitchen instruments for my cooking initiatives or presents for pals.

“It’s the small craft businesses—that’s in point of fact the place the broader market probability is for a majority of these machines,” Applestone says. to this point different computer Co. has raised $6 million and bought 500 Othermills, many to design and engineering labs at colleges and universities. As the corporate expands to serve a broader consumer market, she sees a chance on par with other household instruments—no longer for everyone, however nonetheless mass market. “each person has a toaster. perhaps it can be more like a sewing machine,” she says, with a spread of value points.

TechShop anticipates a equivalent trajectory. “We imagine that a considerable set of the economic system—5, 10, 15%—will give strategy to locally produced supplies, local artists co-creating with consumers,” Hatch says. “and they will leverage this combination of design tools and laptop-aided manufacturing to do it.”

(193)