Brew Objects Like Kombucha With This 3D Printer

want a set of recent dishes? Get composting.

could 7, 2015

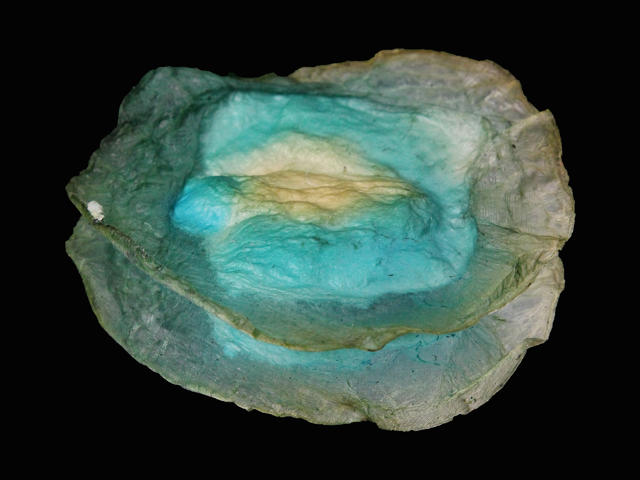

somebody who’s fermented their very own kombucha has encountered the SCOBY—a mucusy colony of yeast and micro organism that floats on the surface to present the tea its funky chew. Dried out, and a SCOBY turns into just a little disc of vegan leather-based. but what if a SCOBY broke freed from its jar? What might it turn into then?

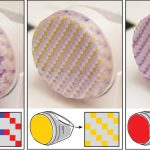

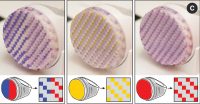

That’s the final premise of Growduce, a conceptual 3D printer by way of Centre de Recherches Interdisciplinaires grasp’s student Aakriti Jain and clothier Guillian Graves. It’s primarily a fermentation tank that you just feed with compostable scraps, and over the path of about two weeks, the SCOBY (now not a true kombucha SCOBY, however very equivalent in organic makeup) will develop into a shape of your liking—starting from bandages to gloves. at the finish of that time, it can be dried out, or even baked, to harden. the remainder cellulose would be sterile, dead skin—like a bacterial-sourced leather-based.

“We understand this most likely requires a shift in fascinated with the supplies we use,” Jain writes in an electronic mail, alluding to the potential squeamish issue of the stuff. “[But] folks in reality drink this and they are alive and healthy!”

The environmental advantage sounds seductive. as an alternative of in basic terms composting our scraps to make soil, we’d be composting our scraps to make new items. anything else you might imagine printing in plastic on a Makerbot could be truthful game for the Growduce. smartly, in thought, at the least.

One catch is that the SCOBY wants a template to grow on. And the most obvious method to produce this sort of template? three-D print it. (In different words, you’d want a regular 3-D printer to make use of the Growduce.) however for disposable items, like, say, SCOBY picnic plates, a plastic template may be reused, churning out plate after plate directly from compost.

whereas the crew has successfully grown SCOBY-primarily based objects on 3-D printed templates, they have got an extended technique to go before the Growduce will change into a fact. They hope to have a working prototype by way of the tip of the year. And after that? it may still be more of a provocation than a mass-manufactured product.

“Growduce embodies a notion process and a potential shift in the way we take into consideration supplies and the production process,” Jain writes. “there is nonetheless a variety of testing that is required earlier than this is something that could hit the shelves and that’s something we wish to work extra on prior to claiming that it’ll be on hand to the market, however we unquestionably hope that gadgets like this will likely revolutionize the way in which we produce everyday objects.”

quick company , read Full Story

(176)