Ceramics get a futuristic makeover

My last trip to Crate & Barrel was exhausting. I just wanted some bowls. But of course, they had to be the right bowls. They had to have just the right volume, but not be too deep or too shallow. I’d bought the wrong bowls before. That wouldn’t happen again. It couldn’t happen again.

But in the end, I walked out of the store with four white bowls that are mostly indistinguishable from any other four white bowls. Because ceramics aren’t customizable. They’re spun on a wheel, or molded in mass produced patterns, in a one-size-fits-all fashion.

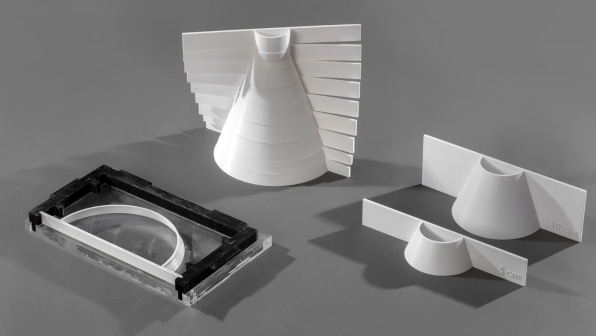

[Photo: Anatoly Krinitskiy]

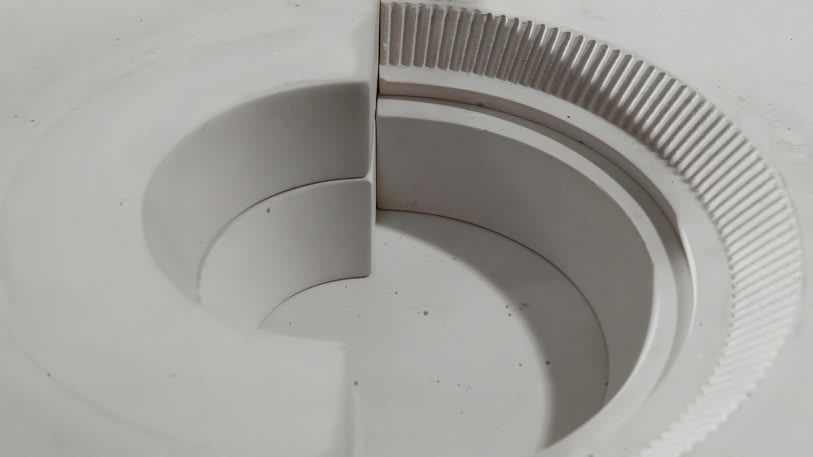

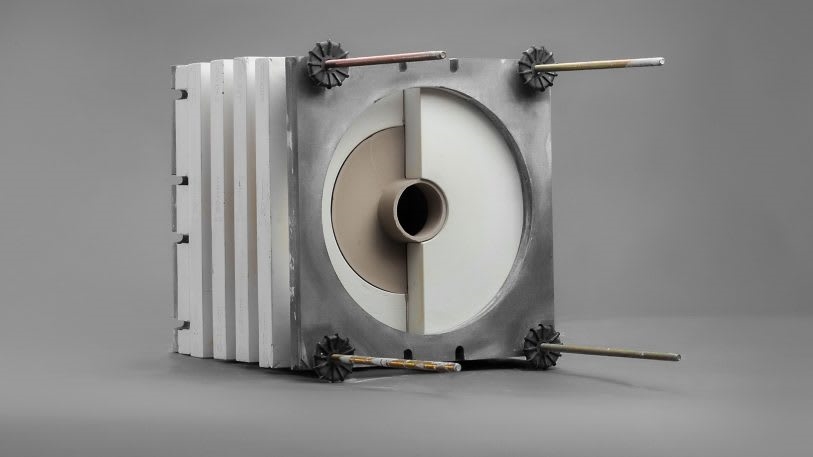

It doesn’t have to be that way, however. Clayers is a project by Aviad Ozery, a student at the Israel’s Holon Institute of Technology, that turns clay pots, plates, and bowls into vessels with modular designs that can be mixed and matched. Ozery has developed a technique that stacks several strata of 3D-printed clay molds onto one another, each of which can be swapped in or out almost like Jenga pieces or Legos. Each of these layers introduces the possibility for new forms, a zig where another mold would have zagged.

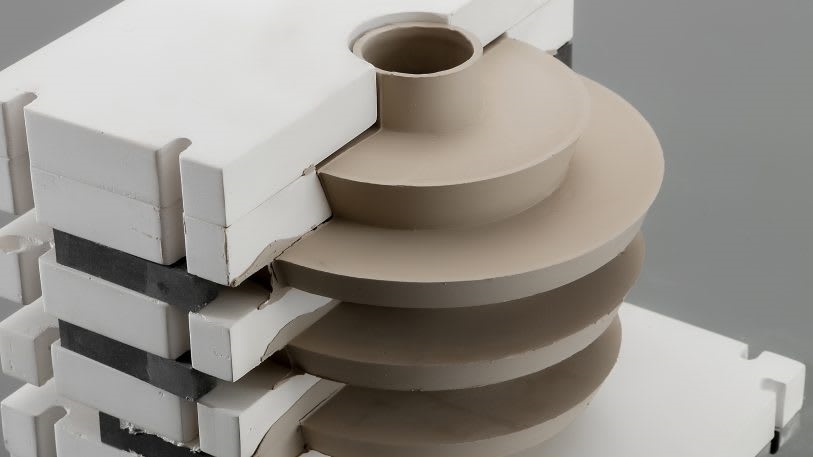

[Photo: Anatoly Krinitskiy]

“I remember standing in a candy store with my mom, furious with her for telling me I couldn’t have more than one of the sweets. Even as a little kid, I was confused by the amount of choice I seemed to have and how limited my options truly were,” says Ozery, recounting his inspiration. “Today we call this the paradox of choice, but to describe how overwhelmed we feel at the vastness of our possibilities. Ceramics is trapped between these two world views—it’s a material that human beings have used for millennia, and yet we’ve limited ourselves to so few forms and uses.”

Small studios produce ceramics by hand with a pottery wheel, or by creating a few molds. Big companies have the scale to support hundreds of molds or more. But anything molded inherently isn’t bespoke. Clayer allows a small studio to start with one mold system and create thousands of different forms from it. The examples Ozery has produced are almost hard to describe. They’re half-serving-tray and half-vase, or a bowl with two heights, or a plate that has a tiny bowl only in its center. And as weird as that sounds, the forms look jointed to your eye. They’re unique but not broken or offensive.

[Photo: Anatoly Krinitskiy]

Ultimately, Clayer introduces the possibility for just a couple of people to mass produce highly personalized pottery. “A smaller studio could easily use this same logic to create a full catalog of products from a single set of molds and be able to customize this across any snack you’d like,” says Ozery. “A dish for olives and their pits, for chips and salsa, or even for the carrots you’ve guilted yourself into eating.”

Into the future, Ozery hopes to find the limits of his own system. He wants to understand the true variety of different mold templates that could come together to form poised objects, which is to say, right now, he’s still at the research phase of his work. But it’s easy to imagine where Clayer’s technology could take an entrepreneur in just a few years: Load an app and customize your dinnerware like it’s a pair of Nike ID shoes. Never buy the wrong set of bowls again.

Fast Company , Read Full Story

(38)