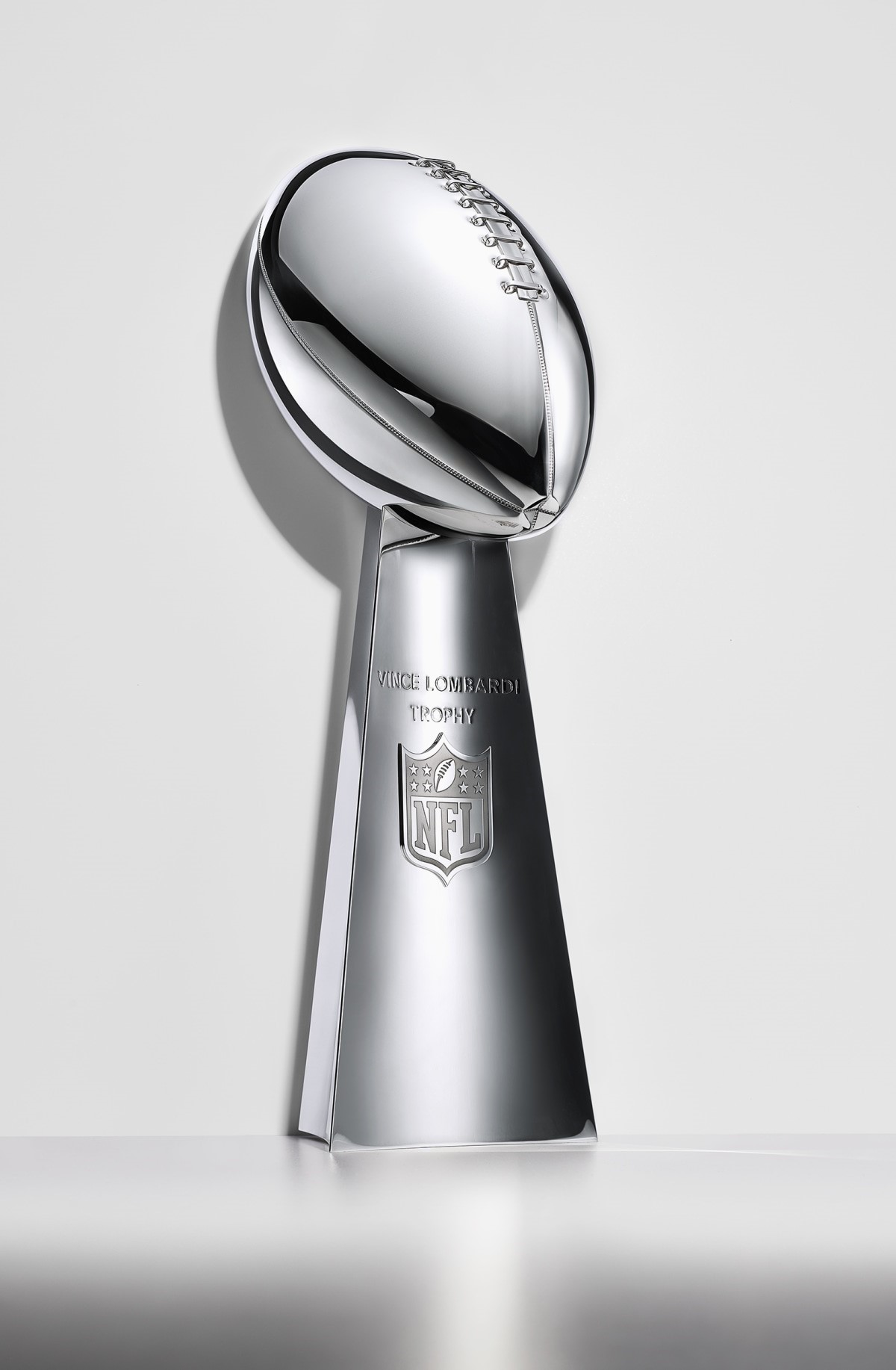

How Tiffany & Co. makes the Super Bowl trophy from scratch every year

If that video of Tom Brady tossing the Vince Lombardi Trophy boat to boat made your palms sweat—or if Gronk bunting with it sent you into hysterics—well, those are appropriate responses. Because Tiffany & Co.’s work on football’s most hallowed prize is a marvel of handcraft rivaling the talent on the turf itself.

As the origin story goes, in 1966 Tiffany & Co. vice president Oscar Riedner sketched the trophy design on a cocktail napkin over lunch with NFL commissioner, Pete Rozelle. While sports history is often defined by a fair amount of lore and legend, when it comes to the Lombardi Trophy that scene “is absolutely true,” says Victoria Reynolds, Tiffany & Co. chief gemologist who previously ran business sales and sports marketing. “I think we all [think of] Mad Men—you know, these two guys sitting there and sketching—but it is, in fact, true.”

Following the Green Bay Packers’s victory in the first two Super Bowls (then dubbed the AFL-NFL World Championship Games), the World Championship Game Trophy was renamed for the Packers’s late coach, Vince Lombardi, who died in 1970.

To Reynolds, the simplicity of the design is what makes the trophy so iconic. But it’s also what makes it a bear to produce, which requires the touch of six artisans over the course of four months.

“It’s really a work of art. And because it’s so simple, any type of mistake would show right away. So, it really has to be perfect,” Reynolds says.

While technical advances have been made in modern silversmithing, Reynolds says that back in 1966, the craft was still rooted in 19th century techniques. Today, the trophy is made in Tiffany & Co.’s hollowware shop in Rhode Island using traditional handcrafting methods.

Work begins with an artisan “spinner”—who Reynolds says was trained by the very silversmith who made the first Lombardi trophy—slowly shaping silver on a lathe. They spin the metal into two halves of a full regulation-size football. The smith has to maintain an equal level of thickness to avoid breaking the silver, which also has to be annealed (reheated) throughout the process to keep it malleable.

“This process is quite taxing—you have to be very strong to do it,” Reynolds says. “Spinning the two halves takes a considerable amount of time.”

Once the pieces are an exact match, a craftsperson solders them together. The visible seam is then polished out, and a hand chaser crafts the seams and laces from silver and installs them. With the football prepped, an artisan then cuts the base out of three large sheets of sterling silver that are bent and soldered together.

When the whole thing is assembled and the football has been docked into kicking position and polished, the trophy is 22 inches high and clocks in at seven pounds. It’s then transferred to the Pro Football Hall of Fame in Canton, Ohio, where it is displayed until the big game—at which point, “under the cover of darkness it is transported to the venue,” Reynolds says. “The security on that is quite something, as you can imagine. It’s done very discreetly. But it’s done with a full security team. […] It’s transported with absolute safety and secrecy.” (Tiffany & Co. declined to disclose the cost and valuation of each trophy.)

After the game and on-field trophy presentation, the Lombardi returns to Tiffany & Co., where the team names, final score and other details are engraved by hand. (“Talk about a nerve-wracking job,” says Reynolds.)

Over the years, the trophy has returned to Tiffany’s workshop in various states. “Usually when we get it back, it’s covered with champagne, which you would expect. But we can always get it back to its pristine condition,” Reynolds says. “There have been times where maybe it’s been loved a little bit too much and it has some nicks and dents in it, and it has to have a little bit of a facelift to go back. But I think again, one of the things that makes a great trophy is when you can really physically love it.”

Tiffany & Co. would know. The company also makes the trophies for the World Series, FedEx Cup, NBA championship, WNBA championship, U.S. Open—seemingly everything except the stalwart Stanley Cup. Reynolds says Super Bowl teams also have the option to buy three-quarter size replicas of the Lombardi Trophy for players and those in their organizations. And they’re all crafted with the same level of detail.

From the spinner to the polisher to the etcher, “Every single one of these people is dedicated to excellence,” she says. “What makes a trophy great is the passion [that] people put into it. I would say this humbly, but I don’t think you need quality assurance at the end of this because every single person feels accountable for it—so the love, the passion . . . when we hold up this trophy, it really signifies the work, the excellence, and the commitment that these silversmiths have.”

(9)