Levi’s wants to invent the jeans you’ll be wearing in 2050

Every year, the average American throws out 80 pounds of clothing, which amounts to 14 billion tons across the entire population. Some of these clothes are donated or sold on the secondhand market. But ultimately, they all end up in the same place: the trash heap. These days, T-shirts, jeans, prom dresses, and shoes make up about 8% of landfill waste. But imagine if you could throw a your ratty old t-shirt or worn-out jeans into the recycling bin, along with your plastic water bottle and aluminum beer can. The clothes would then get sent to a facility where they would be broken down and turned back into new T-shirts and jeans.

Paul Dillinger, Levi’s head of innovation, believes this future is around the corner. And he wants Levi’s to be ready for the day that large-scale clothing recycling becomes available. Levi’s recently launched a capsule collection through its eco-friendlier Wellthread line that is designed to be easily processed by an industrial fabric-recycling plant. “We are building a design practice to retrain designers to design clothes that can be more efficiently taken back, recovered, and turned into next-generation materials,” Dillinger says.

[Photo: courtesy Levi’s]

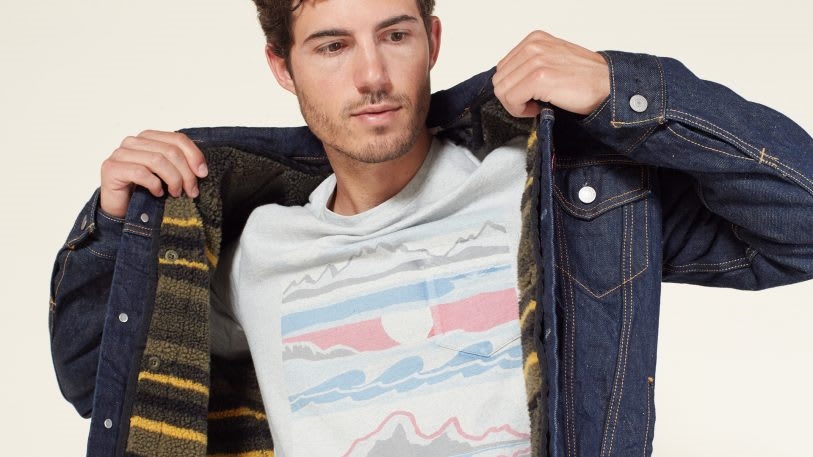

The capsule collection was made in collaboration with surf brand Outerknown. On the surface, it looks much like the other clothes you might find at a Levi’s store. There are graphic tees, Western-style shirts, jeans, and even a trucker jacket. But what’s different about the line is that each item is made from a single material.

It is currently difficult to recycle mixed materials, which is why plastic and aluminum manufacturers have to abide by strict government-mandated standards before an item can be certified recyclable. Since there is no mandate around garment recycling yet, Levi’s designers imposed a material standard on themselves. “It’s a lot of deep R&D on the sundries, the threads, the pocketing, the types of labels,” Dillinger says. “All of these need to be made from the same material and be taken apart easily. But it needs to come together in a way that looks credible, like a thing you already know and want.”

For instance, the T-shirts are made entirely from cotton (including 25% recycled cotton from jeans and other scraps). There is also s fleece-lined trucker jacket that is cleverly designed so you can take out the polyester fleece lining to recycle it separately from the hemp denim. “We very carefully made the fleece detachable from the interior, so you could have a more heavyweight garment that serves the need for the winter season and a lighter one for when it’s warmer,” he says. “When it’s time to recycle it, the liner is made entirely from polyester, from the threads to the label, everything, while the shell is made entirely out of cottonized hemp. When they’re separated, they are the ideal input into both the cotton, cellulosic (fibers made from plants), or polyester recycling system.”

[Photo: courtesy Levi’s]

There are many startups tinkering with sustainable practices: Everlane is working to eradicate virgin plastic from its supply chain, from the synthetic fibers in garments to the plastic bags in which clothes are shipped; Allbirds is designing sneakers from sustainable fibers like wool and tree fiber, while also working to become completely carbon neutral; For Days manufactures T-shirts out of organic cotton, then recycles them when the customer is done with them.

For a large heritage brand like Levi’s—which generates $5.6 billion in revenue a year by selling millions of jeans in 110 countries—it’s not enough to develop a new material or technique. The company’s real challenge is figuring out whether it can execute a particular material or process across hundreds of factories in 30 countries. That’s why the Wellthread line is so important, Dillinger says. “You have to put (the new design) through the supply chain to validate that the opportunity is real and substantiate it in real production scenarios,” Dillinger says. “You can’t do that until you actually make, manufacture, distribute, and sell the product.”

The Wellthread collection is a microcosm of the struggles of large, multinational brands trying to move toward a more sustainable future. One of the risks, Dillinger says, is putting too much strain on its network of existing suppliers by asking them to do things they’re not yet equipped to do. “If we introduce a new practice too fast, or at too large a scale, we put it at risk of failure,” Dillinger says. “We don’t want to get the reputation for being too difficult, too risky, or too problematic. So we need to test things at a smaller scale, then slowly try to introduce them to the rest of the company.”

[Photo: courtesy Levi’s]

If Levi’s were to make all of its products recyclable, it would theoretically be able to divert millions of clothes from the landfill as soon as fabric recycling is available. The question, then, is when fabric recycling will become mainstream. Technology is not what is holding us back, Dillinger says. The problem is that there hasn’t been a concerted effort to create a national fabric recycling infrastructure, like we have with paper, plastic, and aluminum. “There hasn’t been an urgency around the collection, recovery, and repurposing of garments,” he says.

Dillinger points out that the U.S. government had a strong incentive for recycling aluminum as part of the war efforts for both the first and second World Wars, but there was no similar impetus for clothes. “We all knew it was our job to make sure we kept our nation safe by recycling that tin can,” he says. “Kids were dragging their little wagons around the neighborhood to collect more metal. And for that reason, there’s an infrastructure around metal recovery that persists to this day, is robust, and exists in all 50 states.”

Then, in the 1970s, the government invested in creating recycling facilities for glass and paper, thanks to a growing awareness of the environmental impact of waste. But by then, clothing was already so complex, made from fabrics that incorporated different materials, that there was no straightforward way to break it down. Over the past few years, several startups have made breakthroughs in fabric recycling, but they are all experimental for the time being and have not reached enough scale to become mainstream. Evrnu liquifies old textiles and Re:Newcell melts them, before turning them into new fibers, while Worn Again breaks polyester down at a polymer level before reconstituting it.

Dillinger believes it will be hard for any one individual company to create a nationwide clothing recycling system on par with paper or glass recycling. “Its a type of infrastructure that is too large for a single company to take on,” he says. “The companies that are investing in fabric recycling technologies are generally doing it at a loss. It’s too big a lift for a single company to execute, and it’s not anything that a citizen or consumer can do either.”

In other words, Dillinger believes governments will need to create policies to make fabric recycling the norm, while companies and designers need to design clothing that’s ready for recycling. So far, the U.S. government has not made fabric recycling a priority. Some states, such as Massachusetts, encourage residents to donate clothes to retailers that collect clothes to be repurposed or recycled. But other countries are beginning to develop policies that force brands and consumers to be more conscious about the fabric waste they are creating. In the United Kingdom, for instance, a recent bill proposed taxing each item of clothing to fund the creation of fabric recycling infrastructure. It failed to pass in Parliament, but Dillinger believes ideas like this are a sign that change is on the horizon.

“We might be skeptical about the viability of this kind of action in the United States right now, but I think this is a temporary thing,” Dillinger says. “At a macro level, we need to rely on progressive governments to lead the way. But as a company, we need to be much better at designing the product that will be optimized for that infrastructure in the future.”

Fast Company , Read Full Story

(36)