Make Your Outfits on your living room, With This garb 3-D Printer

From digital recordsdata, the Electroloom spins cloth to life—no sewing abilities or cotton container vital.

June 11, 2015

a typical cotton T-shirt has a protracted and complicated history, starting in a pesticide-doused cotton field, touring thousands of miles between processing crops and the garment manufacturing facility where low-wage workers stitch it collectively, and making any other long ride to a retail retailer.

however we’re not necessarily far from a future where any individual can print a T-shirt from scratch by way of themselves from their dwelling.

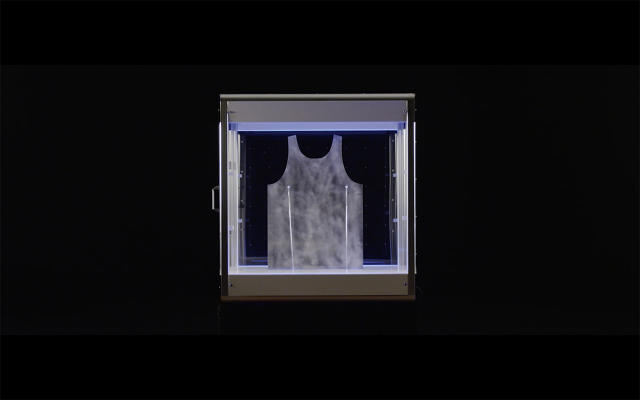

a new 3-d printer for attire can create a simple prototype of a tank prime, without a stitching talents or cotton field required. the method seems to be a little bit like a sci-fi cotton candy laptop, spinning fibers from electrically charged liquid that adheres into cloth inside the area of some minutes.

“quite a few the potential sustainability advantages that may come from this know-how come from the removing of a variety of intermediate steps,” says Aaron Rowley, co-founding father of Electroloom, the startup that created the three-D printer. “We take uncooked materials after which convert them into a non-woven cloth in a single step.”

The startup started with a conversation between the founders: How cool would it not be to make garments on demand? They realized that they may adapt lab expertise that engineers synthetic tissues. After months of experiments, they turned the tiny fibers into a bigger, wearable model.

by means of January, they had been ready to print simple sheets and tubes of their new material, with an end result that appears like a go between cotton and suede. Now they’ve created a few basic items of clothing, spun to lifestyles from digital recordsdata.

“something we predict is really cool is that with this know-how you’ll be able to draft one thing very exact in a digital structure, and then the end product will mirror those dimensions precisely,” Rowley says. “the clothes we prototyped ourselves, together with the beanie, skirt, and tank prime, went from idea, to digital draft, to finished just right in a technique that lets by no means do ahead of.”

the method eliminates waste. At a customary garment manufacturing unit, as so much as 15% of cloth finally ends up as scraps on the slicing room flooring. in a roundabout way, the new subject material may be totally recycled when any person’s performed carrying it.

“we’ve got additionally run experiments that show we can efficiently take a completed subject material and then redissolve it and reuse it to make something completely new,” says Rowley. “that’s somewhat exciting while you imagine the long run—we would possibly at some point be able to recycle worn clothes or fabrics in this type of expertise quite than tossing them in a landfill.”

the material will wish to change ahead of it’s in reality ready for people to put on. “whereas our fabrics are extraordinarily smooth and lightweight, we need to fortify on different vital metrics, like durability and elasticity, in order that what is made can withstand put on-and-tear of every day activities,” Rowley says. “we’re most definitely a couple of iterations or years out from being able to deal with the materials the identical approach as you would most fabrics.”

but rather than keep the brand new expertise locked up in their own lab while they give a boost to it, the team decided to open it as much as others for experimentation. In a Kickstarter marketing campaign, they are providing their prototype to someone who desires to check out to print their own garments.

“We’re giving backers an opportunity to in reality use our technology while being excited about our development cycle,” Rowley says. “We idea this was once a good way to get early remarks, quite than designing in a vacuum.”

[All Photos: via Electroloom]

(115)