These invisible bar codes make plastic more likely to be recycled

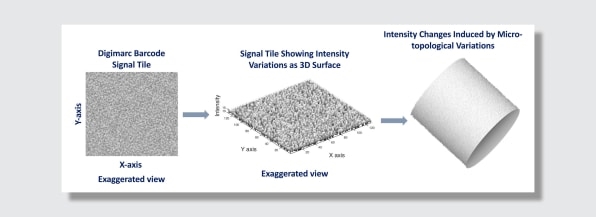

Today, when you recycle a plastic container, it goes to a material recovery facility, where it must be identified and sorted. Facilities typically rely on imprecise older technology to try to figure out materials in a particular piece of waste. Workers standing next to conveyor belts as packages whiz by can catch others. But by embedding a microscopic change in a pattern of pixels—called an invisible bar code—on the label, software can instantly identify the package so it can be sorted and recycled correctly.

Several of the world’s largest brands, including PepsiCo, Nestle, and P&G, have spent the last two years collaborating with Digimarc, the company that developed the technology. Working with recyclers, retailers, and recycling machine manufacturers to test the system, the project aims to target one of the reasons that many plastic packages end up in landfills.

“Obviously, there isn’t one silver bullet solution to the plastic issue,” says Sander Defruyt, who leads the New Plastics Economy initiative at the nonprofit Ellen MacArthur Foundation, which initially brought the companies together when the project began. “We need to start by eliminating the plastic we don’t need. We need a lot of innovation shifting from single-use to reuse business models. But recycling is still one part of the problem, and [brands] realize that to make recycling work, we need to improve the way plastic waste is sorted in sorting centers.”

By sorting more accurately, the final bales of material are more valuable, and the total amount of material that can be recycled increases. The system can identify whether a bottle was used for food or something like shampoo—a crucial step that current systems can’t accomplish but is necessary for food companies that want to buy recycled plastic to reuse in new packaging, as European regulations prohibit them from using recycled plastic that was originally for something other than food.

[Photo: Digimarc]

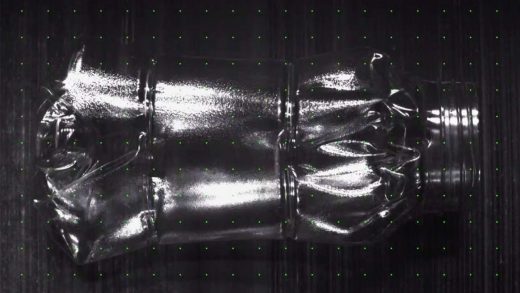

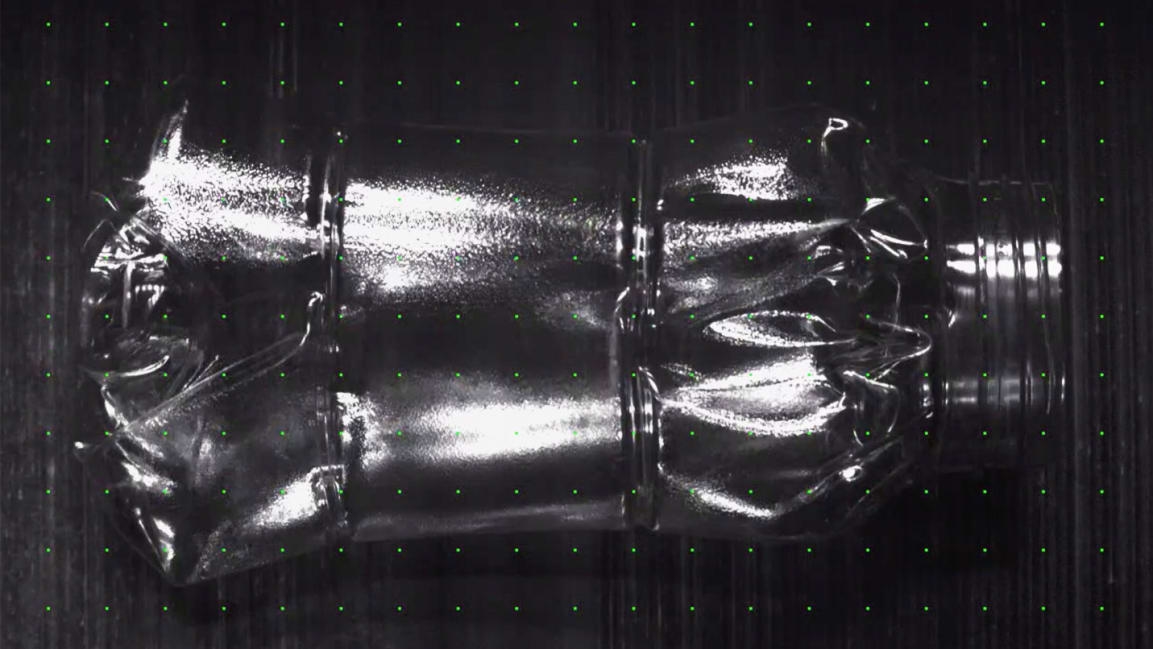

The group of companies also tested a system that involved using a chemical marker that could be embedded in a material. But that added a cost, and because it also added a foreign substance, it meant that some materials couldn’t be recycled back into food packaging. The invisible bar code, by contrast, can be added to a label at no marginal cost with some simple changes in Photoshop. Repeating copies of the bar code are hidden all over each label, so even if a package is crushed and damaged or facing in a particular direction, the cameras can often still see the information.

For packages that don’t have a label, such as a clear plastic takeout box, the bar code can be hidden in a microscopic pattern embossed in the plastic. It’s likely cheaper, overall, than some other approaches to the problem, like robotic systems that use artificial intelligence to sort waste. In a pilot at a German facility used to test recycling technology, the system worked well.

The idea has other benefits. For consumers, an app can scan the code and instantly tell someone if a package can go in their city’s recycling bins (confusion and “wishful recycling,” or putting a package in the recycling bin because someone hopes that it can be recycled, also cause problems in the system). Brands could also embed information about how a product was made or instructions for use. At a grocery store, the invisible bar code could make checkout faster, since the data covers the entire package, and checkers don’t have to search for a code on one side.

Digimarc, a company that makes automatic identification technology, invested $250 million to develop the technology. More than 70 companies participated in the initial pilot, and Digimarc will invite more to join early next year. Now, the company is making the final tweaks in the technology to get it ready to roll out. It’s also going to begin providing the spec that other companies, including the manufactures of sorting equipment, need to make the system work. The system will be installed in a working sorting plant in 2020 and then will roll out in a European country in 2021. For it to be successful, says Defruyt, brands will need to universally adopt it. “The system only works if the entire industry aligns on one common protocol,” he says.

(56)