This 3D-Printing Lab Is Iowa’s Entry Into A $140 Billion Industry

Iowa City is a quintessential college town: It’s hard to delineate where the University of Iowa campus stops and the city begins, and they often work together, the 33,000-student academic hub powering the local economy, much like the heart pumping away in the body.

These days, the city and school, long famous for graduate programs like the Iowa Writer’s Workshop, are making inroads and investments in the fast growing 3D-printing sector. Their specific focus: 3D printed prototyping of medical devices. Iowa City, after all, is home to the University of Iowa Hospitals and Clinics (UIHC), a celebrated and expanding teaching hospital.

In recent years, state and local leaders have adopted a long-term strategy to transfer research from UI’s state-owned entities into private, local enterprises. So far, incubators in an off-campus research park have spun out nearly 100 companies. Still, economic development officials worried they were missing opportunities, specifically in the red-hot medical device field—now a $140 billion industry.

Enter Protostudios, a small 3D-prototyping shop that last May became the inaugural tenant at MERGE, a co-working space for entrepreneurs in downtown Iowa City. Local leaders hope the startup can serve as a catalyst for a new regional industry.

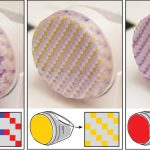

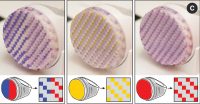

Chuck Romans, Photostudios’ prototyping director, has a master of fine arts degree from UI. He’s an expert at creating functional, aesthetically refined products. With a single computer running CAD and a trio of 3D printers (a Stratasys J750, a Stratasys F370, and a Markforged Mark Two), Romans can often design and manufacture a functional prototype of a medical device in less than 24 hours.

Access to such high-speed prototyping has turbocharged the ability of Dr. Matt Howard, a neurosurgeon and the chair of UIHC’s department of neurosurgery, to improve upon the tools he and his colleagues use every day.

“You see a clinical problem and figure out a solution,” says Howard, who has started four medical device companies over the years. “It goes from a rough concept to one that you refine and refine until you’ve got something that works.” That “something” might be anything from complex electronic implants to a simple tube or a new tongue-depressor design. Howard is exactly the sort of inventor–accomplished, connected, and local–that Iowa and Iowa City officials had in mind when they invested in the prototyping lab.

Protostudios retains none of the intellectual property rights for the prototypes it creates, and as a not-for-profit backed in part by UI’s Office of Research and Economic Development, generally offers far less expensive services than private companies in Minneapolis–home to the country’s largest medical device market and a mere five-hour drive from Iowa City.

“It’s less expensive and radically easier working with Protostudios than with a company in Minneapolis,” Howard says.

As a state-funded facility–Protostudios received a $1.5 million grant from the state’s economic development agency, the Iowa Economic Development Authority (IEDA)–the lab’s success is a state-wide priority. In fact, IEDA envisions Protostudios as both a creator of new companies and a potential source of business for the state’s manufacturing base.

“With Protostudios, we’ve created a service that helps entrepreneurs make products conveniently, economically, and, most importantly for us, in Iowa,” says IEDA director Debi Durham. “The value proposition for entrepreneurs is clear: Come to Iowa, and we can help you make a prototype –medical or otherwise–affordably and conveniently in an absolutely wonderful place to live.”

__

This article was created with and commissioned by the Iowa Economic Development Association.

Fast Company , Read Full Story

(24)