Winds of exchange at Dyson

Can the pioneering vacuum maker transform itself right into a full-blown tech firm? An unique peek inside the house that suction built.

September sixteen, 2015

Sir James Dyson, inventor and honorary Commander of the Order of the British Empire, works out of a pitcher-walled place of work on the 2nd flooring of Dyson world headquarters, within the village of Malmesbury, a hundred miles west of London. the distance is ethereal and brilliant, and stuffed, museum-model, with tokens of Dyson’s design influences: a ebook on the history of the Toyota company, an previous but sturdy plastic Sony flip phone, a toy 1961 Mini Cooper, a die-forged variation of a Nineteen Seventies-era Hawker Siddeley Harrier warplane. “The Harrier was a innovative computer,” Dyson tells me. “it can take off and land vertically, and it had a one-piece carbon fiber wing that made it very, very gentle. It wasn’t the fastest fight airplane out there, but it used to be the one all of the RAF pilots needed to make use of, because its excessive lightness made it so maneuverable. And, of course,” he emphasizes, “it was once a British invention.” a couple of years ago, Dyson situated an actual-lifestyles decommissioned Harrier jet on the web and paid to have it hauled from an airfield in nearby Essex to Malmesbury. It now sits at the primary entrance to Dyson HQ, directly beneath the founder’s workplace windows.

At 6-foot-1, Dyson is all angles—jutting jaw, slender fingers, reported cheekbones. In advertisements, and within the pictures that seem on the containers of Dyson vacuum cleaners, he generally eschews glasses, but across the office, he favors a round pair that give him an owlish seem to be and amplify the intensity of his blue eyes. On the June day we meet, he is sporting a steel-strap Suunto Ventus watch, along with a button-down shirt and drawstring pants designed by using his daughter, Emily, who owns a popular boutique in London. He apologizes for running late: He’d spent the afternoon downstairs within the R&D lab, inspecting prototypes. “It was difficult to become independent from,” he says. “i will be able to’t man the lathe anymore, but i will be down there daily, going from project to challenge.”

Dyson is 68. His air-circulation-product endeavor, which did an organization-record $2.1 billion in international sales final yr, has given him a net value at the moment estimated to be just shy of $5 billion. no longer quite, he is incessantly asked if he will ever take the industry public. He all the time demurs. “I’ve at all times idea it relied on what kind of company you wanted to be, whether or not or now not you bring in different shareholders,” Dyson says. “Our pastime is in know-how and engineering and design, and as a family business, we’re ready to maintain the point of interest and philosophy there. We’re able to think very long-term, to develop technology that might be 20 to 25 years away. we can have enough money to do it. we are able to have the funds for to make errors without anyone being sacked. we are able to take a long-term view of the whole thing.”

He gestures to the products lining the partitions of the room, a highlight reel from Dyson’s 22-yr company history that seems to show his level effectively: The DC01, the primary Dyson vacuum cleaner constructed for the U.okay. market, and a national easiest vendor. The DC07, with its Lamborghini-yellow paint job and translucent bin. The digital-motor-powered V6 Absolute, a cordless surprise that retails for a cool 500 bucks. The Airblade hand dryer. The round Air Multiplier—essentially a fan without blades—and its elliptical, local weather-controlling cousin, the hot + Cool. With this kind of success, Dyson acknowledges, there’s all the time the temptation to “rest in your laurels, to slap your title on extra merchandise, to think in simple terms when it comes to trade selections. but,” he smiles, “that’s now not where I’m headed.”

as a substitute, Dyson is aiming for a daring and potentially risky enlargement of his model, which some staff have taken to calling “Dyson 2.0.” last yr, the corporate broke floor on a more than $four hundred million expertise campus adjacent to the Malmesbury headquarters. When it is completed subsequent 12 months, it will house 3,000 designers and engineers. Already, the corporate has brought in a whole lot of device and laptop hardware consultants and tripled the size of its engineering body of workers. the corporate currently funnels $2.5 million into R&D a week; it has spent $8 million on a chopping-area robotics research lab at Imperial school, in London, and put another $15 million within the American-primarily based stable-state battery firm Sakti3.

In coming months, the expertise campus will function a launching pad for a spread of new verticals, some of which Dyson has disclosed (robotics), some of which appear imminent (the Sakti3 funding appears to indicate an additional hobby in family electronics), and some of which can be fully classified. meanwhile, a few months before I arrived in Malmesbury, Dyson introduced it was once acquiring the LED lights company founded by James’s eldest son, Jake, and bringing Jake on board as a senior govt. (Jake and his younger brother, Sam, the owner of a report label, Distiller, both have seats on the board of directors.) Jake’s lights can be offered below the Dyson identify; all manufacturing will probably be transferred to the Southeast Asian services used by Dyson correct, and Dyson will gain market share in yet another industry.

If Dyson has no real interest in an IPO, does Jake’s new position at the company sign that he may at the least be taking a look to step again a bit of? Dyson swears to me that he has zero passion in retiring; the very word sent him jolting forward in his leather-based chair. “No,” he says. “No, no, no.”

nonetheless, it’s impossible not to see the entire adjustments underfoot at Malmesbury—the brand new campus, the brand new products, the newly empowered son—as an effort to sit up for the following act in Dyson’s evolution as a brand, one with the intention to be outlined, at least partly, through a recent influx of skill and ideas. If it succeeds, Dyson may no longer be known as a cutting-side appliance firm, but as a slicing-facet know-how firm, full stop.

Steve Wozniak and Steve Jobs had the Apple I. invoice Gates had normal. James Dyson had a worn-out Hoover Junior vacuum cleaner that he jury-rigged with a cardboard cone—a scaled-down version of a tool he’d as soon as observed, as a budding inventor, at a nearby sawmill. The mill’s “cyclone” used centrifugal pressure to spin dust out of the air. Dyson’s prototype vacuum did the same with household particles. In 1983, a eastern company agreed to sell the laptop, which had a clear bin, for a listing price of just about $2,000. It used to be a success. the primary vacuum Dyson built after beginning his own firm, in 1993, also featured a transparent bin. “We did market research and discovered that nobody needed to see the filth,” Dyson says. “but as engineers, we couldn’t keep in mind that. We beloved seeing what went on inside—how so much the computer picked up each time you ran it. So we omitted the research.”

He nonetheless hasn’t given it another glance. Dyson, which owns 20% to 30% of the vacuum market in Europe (relying on which white paper you consult) and 6% within the U.S. (in keeping with Euromonitor), has lengthy touted the very best suction power of its vacuum cleaners, however much of the persevering with reputation of the brand has to do with Dyson’s purposeful transparency. The products, and the prices they command, confer a status on the owner in the identical way a MacBook professional does: here is a one who is prepared to put money into type and quality. certainly, in England, Dyson staff are aware of having their firm compared to Apple underneath Steve Jobs. but the analogy can chafe. a few Dyson staffers I spoke to pointed out that Apple incessantly puts the emphasis on design for design’s sake, deliberately shrouding the workings of its computers—anathema to Dyson ideology.

just a few hours after I meet with Dyson in his place of work, I stand with engineer Mike Aldred on the fringe of a small variation lounge the corporate makes use of to blow their own horns new technology. He locations Dyson’s newest product, an self sufficient vacuum cleaner known as the 360 Eye—talked about around Malmesbury merely as “the robot”—on the carpet. The vacuum, which has been within the works for more than 15 years and will go on sale in Japan in December, and in Europe and the U.S. early subsequent yr, is identifiably a Dyson creation, with a digital motor and familiar cyclone cones seen within a see-through bin. on the same time, the software is naturally an important jump forward for Dyson into computer programming, tool design, the web of issues. “It used to be an extraordinarily, very steep learning curve,” Aldred says. “after we first began out on the robotic, we had great motor groups however now not quite a few electronics experience.”

For help, he became to a dozen hardware specialists and tool developers poached from British tech firms who better the 360 Eye’s laptop systems and created a brand new Android and iOS app. “We’ve polished this thing except it’s precisely proper,” Aldred says. He digs his iPhone out of his pocket and swipes a finger across the reveal. The robotic hums to lifestyles, and dealing its approach outward from the guts of the room, climbs up a short ledge and weaves between a pair of desk legs. confronted with the threshold of an armchair, it stops and appears to fall into deep thought. “It’s extremely light, and all of the weight is on the chassis,” Aldred says, conversing as a father would of his star athlete son. “so as it comes to one thing, it’s going to just gently nudge it, detect that it’s hit something, and go, ‘Oh, okay! Time to back off and transfer away.’ ”

Aldred says that Dyson may have launched the computer past however stored ready: The batteries weren’t lasting long enough, the sensors were too finicky, the digicam had blind spots. “There are moments, clearly, whilst you’d love to look your product available in the market,” Aldred says. “however I’d hate to have it out there figuring out it could be better. and i’m fortunate, having any person like James, who is ready to let us spend all this time getting it exactly right.”

He factors to his iPhone, which shows a map of the world the vacuum covered. “Now what’s good,” he goes on, “is let’s say you’ve gone out for the day and programmed it to wash the whole ground floor, but you forgot to go away a door open. it will understand that what is still to be cleaned, and when you get back home, that you can put it back off in that uncleaned house, and away it’ll go.”

within the 15 years Dyson spent painstakingly perfecting the 360 Eye, a variety of independent ground cleaners have entered the market, including iRobot’s Roomba and a few fashions from Samsung. Dyson says that the 360 Eye will supply better suction, extra evolved sensors, and longer-lasting battery existence than its rivals. still, in a way, the instrument is illustrative of the challenges Dyson faces because it attempts to extend into classes already thick with deep-pocketed rivals: What occurs when a company accustomed to being hailed for its improvements decides to play seize-up?

more than 2,000 folks work on the Dyson advanced in Malmesbury, a lot of them recent-faced and hoodie-clad. (strolling the serpentine halls of the main constructing, you’d be forgiven for pondering you’d arrived on the home base of a Silicon Valley tool developer.) however best a small fraction are allowed to step foot within the research and building area, which lies in the back of a collection of frosted glass doors—and a finger-print scanner—on the bottom flooring.

guests are uncommon right here, and journalists extraordinary. with a view to achieve get right of entry to, I had to give up my voice recorder, place my iPhone in a sealed plastic bag, and don a bright blue-and -yellow vest, so staff would be capable to see me coming and have sufficient time to drop a tarp over anything off-limits. “We’re extremely careful about security,” Alex Knox, the worldwide new construction director, says by way of apology. (no longer that it’s at all times paid off: In 2012, Dyson said it caught a former worker selling private documents to a rival.)

The birthplace of lots of the company’s major improvements, the R&D area is the place the subsequent 10 years of Dyson devices are being crafted. “We’re on a design-build-take a look at loop,” explains Knox. Over the course of a standard week, the company’s prime-secret New Product Innovation staff comes up with a dozen prototypes, that are modeled and proven off to different engineers. probably the most promising, irrespective of how reputedly some distance-fetched, are despatched up the food chain to the top professionals, steadily to James Dyson himself.

Knox, the 1/3 engineer recruited through Dyson within the 1990s—his first gig was once engaged on the design of the original DC01—helps to oversee that process. “way again in the day, the prototypes would be cardboard, or they’d be built with the aid of in-house model makers,” he says, pushing open the door to a room dominated by way of a big metal crate. “Now we’ve gotten slightly extra advanced.” The crate, Knox explains, is an EOSINT P 760, an $800,000 instrument that uses lasers to sinter prototypes out of steel powder. An engineer may work up his prototype with CAD device on one of the vital computer systems down the corridor, he says, and have it in hand by the top of the day.

Our next cease is the EMC chamber, a room used to test prototypes for electronic or radio interference with other gadgets. The 20-foot walls are coated in large slabs of froth that absorb extraneous sound; there’s no testing occurring at the moment, and the quiet is unearthly. The room subsequent door is bristling with microphones that measure the sonic output of Dyson merchandise. “We need to make sure there are not any unpleasant sounds,” Knox says, “for the reason that sound a tool makes will also be as necessary as the way in which it seems to be, or the way it performs.”

Dyson is fond of claiming that it overtests its units, a ways beyond the parameters stipulated by way of U.S. or European regulating businesses. ahead of leaving the R&D house, Knox leads me into a small trailer the place a late-version vacuum cleaner is being run, with the aid of a robotic arm, back and forth throughout a stretch of carpet. this will likely proceed for 50 hours or extra, Knox says. local, on the wall, are canisters of particles: One is marked SAND, and another, KITTY LITTER.

“It’s not simply kitty litter,” Knox grins, turning the canister towards me. “See? It’s marked jap kitty litter. We like to verify we cater to all totally different varieties of markets.” (There was an American/European kitty litter sample, too, he assures me.)

All this testing serves a function, Knox continues. best via virtually endless repetition can you truly discover what doesn’t work, and what does. “We’ve discovered it can be in reality serendipitous,” he says, and offers an example: Heavy-responsibility testing on the primary cyclone vacuum cleaners led engineers to realize that a by way of-manufactured from the suction was once a so-known as coandra effect—air might be directed to spit out as quickly because it had come in. The Airblade hand dryer followed, which led to the Air Multiplier.

“There are other ways innovations turn up,” says product innovation head Stephen Courtney, who devised the first Dyson Ball vacuum cleaner to handle maneuverability concerns on earlier machines. “It’s not at all times simply considering of an idea. while you’re checking out issues, when you’re observing everything correctly and if the engineers themselves are doing the exams, which you could make these incredible leaps.”

Dyson will unveil the result of one such breakthrough “within the near future,” the company says. all through my time in Malmesbury, i am given a preview of the tool—if truth be told the precursor to a whole new line of merchandise—below the situation that I not disclose any details about it. Suffice to claim that the product represents each a radical departure from and a logical extension of the Dyson model.

Dyson himself provides me a demo in his administrative center, putting off the laptop from a metal field that appears as if it may well withstand a tank shell. He turns it backward and forward, marveling at its shapely lines. he’s happy with it, naturally, and concurrently wowed through it. This particular amalgamation of motor and metal, he believes, is usually a major part of the future of his company.

once this software launches, I ask, are there another markets he’s wanting to get into? He answers indirectly. “i believe the better approach to consider it is that we’ll best get into a field if we consider we can change into it—if we’ve got the technology to actually make a distinction. This isn’t a commercially pushed venture,” he says of the corporate. “It’s no longer about simply making good industry decisions. It’s about way more than that.”

It’s about discovering perfection.

Jake Dyson’s lights industry is situated in an previous elevator manufacturing unit in Clerkenwell, London’s design district. The flooring are rough wooden, the walls gallery white. A sliding garage door opens up into the primary room, and Jake will often pressure his bright purple Fiat 500 directly inside of and park it next to his desk. Downstairs, within the basement, worktables are stained with grease and strewn with wrenches and spare bulbs.

On the day I discuss with, staffers are busy testing a brand new overhead mild, code-named Ariel, which Dyson will release in late 2015. Ariel is rectangular and lengthy, with the large steel wings of a satellite; Dyson sees it basically as a business product, for eating places and lodges. “With most LED downlights they’ve to place diffuser over the top, and you get this glare,” says lighting fixtures specialist Karoline Newman. “it may be unpleasant. Ours is way more focused and direct.”

“And we can use it with baffle blades, which will crop the light to make it precisely suit your place of business,” provides senior engineer Doug Inge, in order that the light can drop off exactly the place a table does, for instance. “You get this magical, focused illumination.” He flips off the home lights, leaving best the glow of the Ariel; the light is precise, clear, sharp.

Over the following couple of months, a number of of Jake’s lighting fixtures engineers will subscribe to the core Dyson group in Malmesbury, but Jake plans to keep his creative crew right here in London. “We’ve fashioned excellent relationships with native architects and lighting fixtures designers, and so they come and spot us ceaselessly, and we get feedback,” he says. “it’s important to be here for them to come out and have a coffee with you.”

Jake, 42, has tousled ginger hair, blue eyes, and his father’s quiet depth. (“We’re both very expertise; we adore making things and designing them, engineering them,” James says of Jake. “We both consider in the identical things, which isn’t relatively true of my other two kids.”) Jake grew up within the Wiltshire nation-state and studied industrial design at imperative Saint Martins. “I enrolled with no person understanding who James Dyson used to be and left with him being tipped as the best British inventor/fashion designer of his generation,” Jake recalls. “It was rather a change.” nevertheless it was additionally somewhat of a burden. After 5 put up-college years in Malmesbury, growing products with Dyson’s New Product Innovation group, Jake left in 2004 to open his own trade.

He discovered a work area in London and spent some time developing a new breed of ceiling fan—”it created two hurricanes within the room and oscillated round; reasonably deadly, in fact,” he says—before shifting into lighting, a multibillion-greenback trade that looked as if it would Jake to be stuck in a bygone generation. The merchandise he present in showrooms were pricey, and their know-how unevolved. Jake knew that he wanted to work with LED bulbs, which last for much longer and consume much much less energy than their incandescent counterparts. but he speedy encountered the identical drawback that had befuddled different engineers: LED bulbs are extremely exhausting to chill properly. “We looked at numerous different options. energetic cooling, with motors and pumped fluids and fanatics, is very efficient, however you get a variety of noise. We needed sturdiness and lifetimes of 37 years, at 12 hours a day,” Inge says. “We had various customers say, ‘smartly, I’ll be lifeless by using then.’ And we’d say, ‘That’s the purpose.’ ”

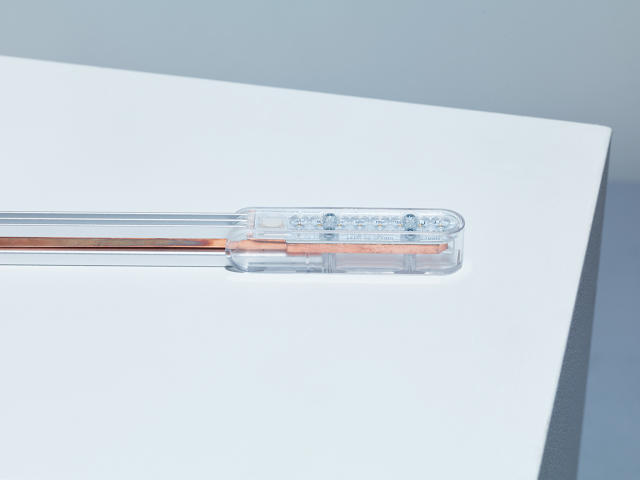

In 2011, Jake and his colleagues settled on an answer: an oblong aluminum rod that sucked warmth away from the LEDs. In correct Dyson type, the function of Dyson’s first LED light, called the CSYS (brief for coordinating gadget), dictates its form: it’s stripped of embellishment, decreased to a sturdy, T-shaped alloy body. Eight LEDs are installed at the end of a boom impressed by way of a development crane. a tap of the finger sends the increase shuttling from left to right; any other tap adjusts the elevation. The software went on sale in Europe in 2012 for $699. through remaining year, Jake was once offering to 405 sellers in 27 nations (a U.S. model is due in late 2015). He and his team had been still building every unit in shop, at a grueling percent.

For years, Jake had held off on returning to Malmesbury—he’d wanted to show himself first. Now that he had, why no longer sign up for forces along with his father? Malmesbury could offer the R&D and manufacturing energy he’d need to develop. more essential, he may offer protection to his father’s imaginative and prescient. “I might never take a seat by and watch a company company are available and spoil it. and they would!” he exclaims, eyes widening. “they might just play on the logo, with out a growth in know-how. they’d break it.”

In a way, Jake, who will spend the following 12 months managing the lighting fixtures vertical whereas getting up to the mark on the hundreds of products under manner in Malmesbury, is the ideal ambassador for Dyson 2.0: an inventor steeped in traditional engineering, but raised within the electronic age. right through our dialog, he stresses the significance of investing in device and pc hardware and units that would fit into the web of issues. “The industry can have to alter slightly,” he says. “All businesses do, to stay on top.” He pauses and toys with the base of the CSYS mild in entrance of him. “but i think it’s important not to concern too much concerning the markets or upcoming trends. the secret is to center of attention on Dyson’s core strength”—constructing sturdy, revolutionary products. “You should take being afraid out of the equation,” Jake says. “Is it that you can think of? And am I eager about it? If the answer is sure, then you definitely go for it.”

Jake, James Dyson admits, “is going to be far more inventive and adventurous than me, almost definitely. however the benefit to the way in which we’ve structured issues is that the important philosophy will carry on. It’s now a domestic industry.” And he’s at all times played the long sport.

[All Photos: Kate Peters]

quick company , read Full Story

(220)